Products

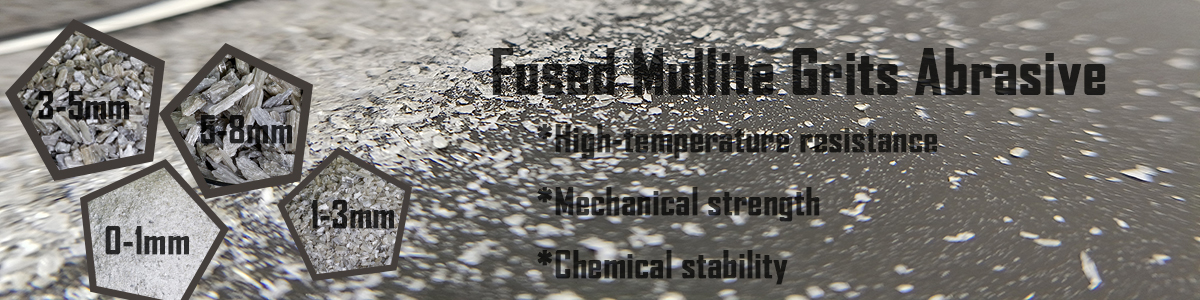

Customized Specification 1-0mm 3-1mm 5-3mm 8-5mm Blasting Media Fused Mullite Grains 79% Molten Mullite Grits

Fused Mullite Description

Fused Mullite has excellent thermal stability, high strength, low thermal expansion, and good chemical resistance. It is known for its exceptional refractory properties, making it suitable for various high-temperature applications. Some common uses of fused mullite include: Refractory Applications, Ceramic Industry, Foundry Industry, Abrasives, etc.

Fused Mullite Specification

| Product Sizes Segmentation | |

| Section sand | 1-0mm; 3-1mm; 5-3mm; 8-5mm |

| Brand | XINLI Abrasive |

| Applications | Refractory, castable, blasting, grinding, lapping , surface treatment, polishing |

| Product Chemical Composition | |

| Al2O3% ≥ | 74-79% |

| SiO2 | 20-25% |

| Fe2O3 | ≤0.1% |

| MgO | / |

| Product Characteristic | |

| Linear Expansion Coefficient (1/°C) | -6.0×10-6 |

| True Density | 3.10 g/cm3min |

| Glass Phase | 5 %Max |

| Porosity | 6% |

| Melting Point | 1830°C |

| *Customized products: We can provide customized fused mullite products with different models and chemical specifications according to customer requirements. | |

Fused Mullite Features

Fused Mullite is a valuable material in industries where high-temperature resistance, mechanical strength, and chemical stability are essential. Its versatility and reliability make it a preferred choice for demanding applications in the refractory, ceramic, and foundry sectors.

- Refractory Applications: Fused Mullite is widely used in the production of refractory bricks, castables, and other refractory products. Its high refractoriness, resistance to thermal shock, and low thermal conductivity make it ideal for lining kilns, furnaces, and other high-temperature industrial equipment.

- Ceramic Industry: Fused Mullite is used in the manufacturing of advanced ceramics, such as crucibles, thermocouple protection tubes, and kiln furniture. Its excellent thermal stability and resistance to chemical attack make it a preferred material for ceramic applications.

- Foundry Industry: Fused Mullite is utilized in the foundry industry as a material for molds and cores due to its high-temperature strength and dimensional stability.

- Abrasives: Fused Mullite can be processed into abrasive grains that are used in grinding wheels, cutting tools, and other abrasive applications. Its hardness and toughness contribute to its effectiveness as an abrasive material.

Your Inquiry

If you have any questions.Please feel free to contact us.

inquiry form

Write your message here and send it to us