Products

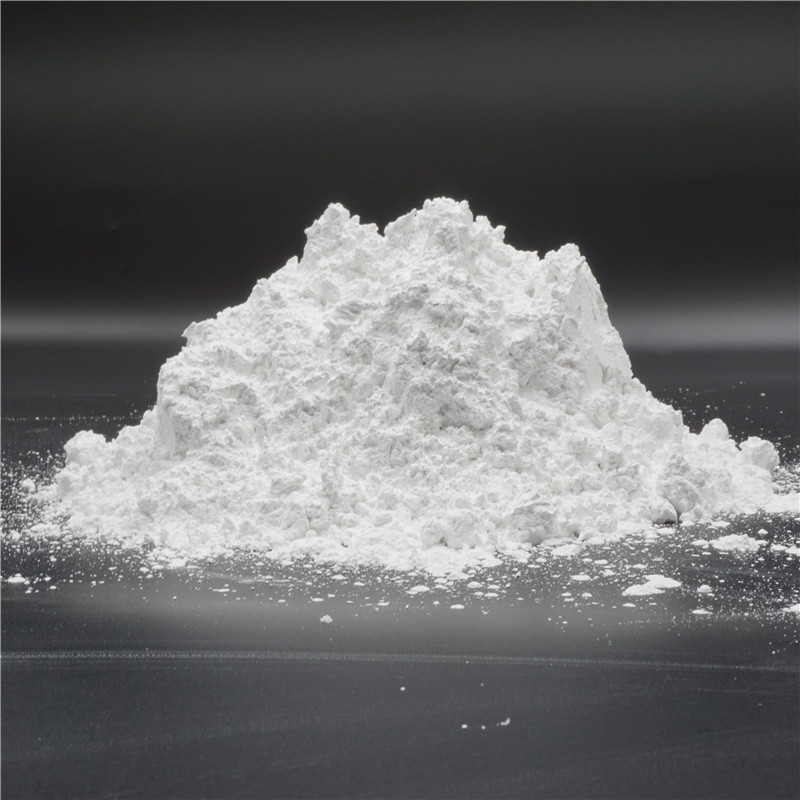

WFA White Aluminum Oxide Powder

White fused alumina powder is made of high-purity low-sodium alumina powder by melting at the high temperature, cooling crystallization, and then crushing. The white fused aluminum oxide powder grit is under strict controlling to keep the grain size distribution and the consistent appearance.

The grain size distribution of the white fused alumina powder is narrow. After shaping processing, high purity white corundum powder has full grain, sharp edges and corners, high grinding efficiency, high polishing brightness. The grinding efficiency is much higher than the soft abrasives such as silica.

Because of the good appearance, the surface of the polished object has a high finish. Widely used in the grinding and polishing of semiconductors, crystals, circuit boards, aluminum, steel, stainless steel, stone, glass, etc. Especially in the industry of grinding and polishing of stainless steel, aluminum, copper and other metal materials and glass industry, it fully demonstrates the superior performance.

White Fused Alumina Powder

White, α crystal over 99%, high purity, high hardness, and high toughness, strong cutting force, strong chemical stability, and strong insulation.

| Crystal form | α trigonal system |

| True density | 3.90 g/cm3 |

| Microhardness | 2000 - 2200 Kg/mm2 |

| Mohs hardness | 9 |

White Fused Alumina Specifications and Composition

|

Particle size specifications and composition |

|

|

JIS |

240#,280#,320#,360#,400#,500#,600#,700#,800#,1000#,1200#,1500#,2000#,2500#,3000#,3500#,4000#,6000#,8000#,10000#,12500# |

|

European standard |

F240,F280,F320,F360,F400,F500,F600,F800,F1000,F1200,F1500,F2000,F2500,F3000,F4000,F6000 |

|

National standard |

W63,W50,W40,W28,W20,W14,W10,W7,W5,W3.5,W2.5,W1.5,W1,W0.5 |

|

Chemical composition |

||||

|

Grains |

Chemical composition(%) |

|||

|

|

Al2O3 |

SiO2 |

Fe2O3 |

Na2O |

|

240#--3000# |

≥99.50 |

≤0.10 |

≤0.03 |

≤0.22 |

|

4000#-12500# |

≥99.00 |

≤0.10 |

≤0.05 |

≤0.25 |

01

There is no influences about the color of processed parts.

02

It Can be used in the processes where the iron powder residue is strictly prohibited.

03

Shaping grains are very suitable for wet sandblasting and polishing operations.

1.Sandblasting, polishing and grinding of metal and glass.

2.Filling of the paint, wear-resistant coating, ceramic, and glaze.

3.Making of oil stone, grinding stone, grinding wheel, sandpaper and emery cloth.

4.Production of ceramic filter membranes, ceramic tubes, ceramic plates.

5.Production of polishing liquid, solid wax and liquid wax.

6.For the use of wear-resistant floor.

7.Advanced grinding and polishing of piezoelectric crystals, semiconductors, stainless steel, aluminum and other metals and non-metals.

8.Specifications and composition

Your Inquiry

If you have any questions.Please feel free to contact us.