Products

Alumina powder for polishing

Alumina powder is the ideal for aluminium production and others that require hardness and resistance to abrasion or other forms of chemical wear. Alumina powder is also ideal for products that require corrosion and wear resistance, and for products that require high thermal conductivity, such electrically and thermally insulating applications.

Product performance:

The product is white powder or fine sand and has good sintering activity. Insoluble in water, insoluble in acid, alkali solution. The particle size of protocrystal is controllable.

Alumina Powder Specifications

| Grains | 0.3μm, 0.5μm, 0.7μm, 1.0μm, 1.5μm, 2.0μm, 3.0μm, 4.0μm, 5.0μm | ||||||

| Specifications | AI2O3 | Na2O | D10(um) | D50(um) | D90(um) | The original crystal grain | specific surface area(m2/g) |

| 0.7um | ≥99.6 | ≤0.02 | >0.3 | 0.7-1 | <6 | 0.3 | 2-6 |

| 1.5um | ≥99.6 | ≤0.02 | >0.5 | 1-1.8 | <10 | 0.3 | 4-7 |

| 2.0um | ≥99.6 | ≤0.02 | >0.8 | 2.0-3.0 | <17 | 0.5 | <20 |

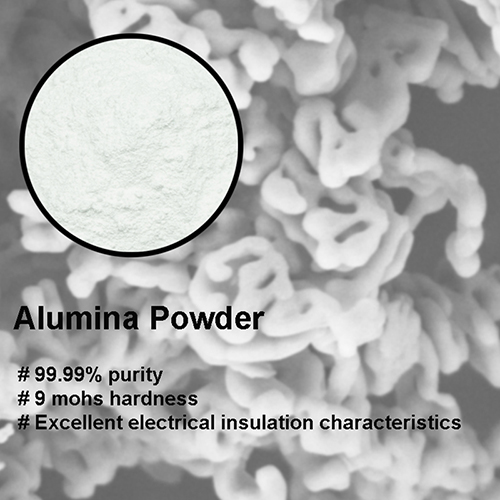

Alumina Powder Characteristic:

1. Chemical resistance

2. High-purity alumina, alumina content greater than 99%

3. High temperature resistance, the Working temperature is 1600 ℃, up to 1800 ℃

4. thermal shock resistance, stable and hard to crack

5. Moulding by casting, it has high density

Alumina powder has the advantages of high purity and high density, mainly used in ceramics, glass, plastics, textiles, building materials, abrasives, paper and medicine, and many other fields.

Alumina Powder Advantage:

1.Through the airflow mill and five layer classification, the grain size distribution is narrow, the grinding efficiency is high, the polishing effect is good, the grinding efficiency is much higher than the soft abrasives such as silica.

2.Good particle appearance, the surface of the object to be polished has a high degree of smoothness, in the last fine polishing procedure, the effect of the grinding and polishing is better than white corundum powder.

1.Phone screen polish, including the final polishing for sapphire cell phone screen, cell phone glass screen. Can also be used: artificial gems, zircon, high-grade glass, natural stones, jade, agate and other vibratory finishing (machine polishing, roll polishing), manual polishing (grind polishing)etc.

2.Metal polishing, including mobile phone shell, car wheels, high-grade hardware final polishing.

3.Widely used in the grinding and polishing of semiconductors, crystals, aluminum, steel, stainless steel, stone, glass, etc.

4.Especially suitable for the mirror effect grinding and polishing of stainless steel, copper, other metal materials, and the glass industry.

Your Inquiry

If you have any questions.Please feel free to contact us.