Products

Platelet Calcined Alumina Powder

Plate Calcined Alumina polishing powder is made of high-quality industrial alumina powder as raw material, and processed by a special production process. The crystal shape of the produced alumina polishing powder is hexagonal flat like tabular shape, so it is called Platelet Alumina or Tabular Alumina.

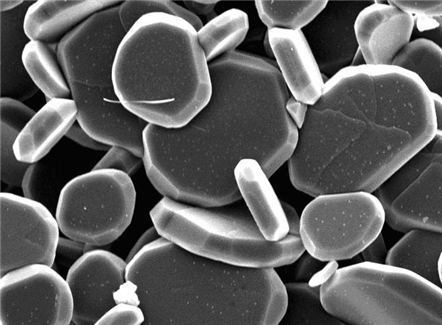

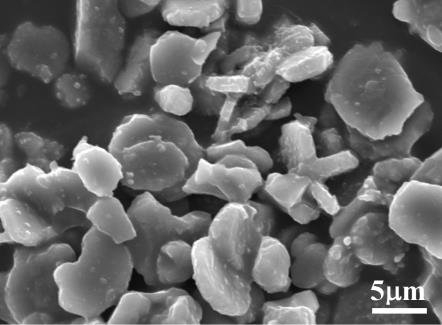

Platelet Alumina is a high quality alumina type abrasive powder, consisting of a plate-shaped crystal of Al2O3 with a purity of over 99.0%. It has excellent heat resistant properties as well as being chemically inert, and is not corroded by either acids or alkalines. As the particle size distribution of Platelet Alumina is tightly controlled, it can produce a very fine lapped surface, giving it superlative effectiveness as an abrasive. With a tremendous range of utilizations, Platelet Alumina is an abrasive powder capable of performing a myriad of functions.

Tabular alumina powder

Tabular alumina powder

Standard Specifications for Particle Size

|

Particle |

Particle Distribution (µm) |

|||

|

Maximum particle |

Particle size |

Particle size |

Particle size |

|

|

45 |

<82.9 |

53.4± 3.2 |

34.9± 2.3 |

22.8± 1.8 |

|

40 |

<77.8 |

41.8± 2.8 |

29.7± 2.0 |

19.0± 1.0 |

|

35 |

<64.0 |

37.6± 2.2 |

25.5± 1.7 |

16.0± 1.0 |

|

30 |

<50.8 |

30.2± 2.1 |

20.8± 1.5 |

14.5± 1.1 |

|

25 |

<40.3 |

26.3± 1.9 |

17.4± 1.3 |

10.4± 0.8 |

|

20 |

<32.0 |

22.5± 1.6 |

14.2± 1.1 |

9.00±0.80 |

|

15 |

<25.4 |

16.0± 1.2 |

10.2± 0.8 |

6.30±0.50 |

|

12 |

<20.2 |

12.8± 1.0 |

8.20±0.60 |

4.90±0.40 |

|

9 |

<16.0 |

9.70±0.80 |

6.40±0.50 |

3.60±0.30 |

|

5 |

<12.7 |

7.20±0.60 |

4.70±0.40 |

2.80±0.25 |

|

3 |

<10.1 |

5.20±0.40 |

3.10±0.30 |

1.80±0.30 |

Quality Standard

|

Type of product |

Specific Gravity |

||||

|

Al2O3 |

SiO2 |

Fe2O3 |

Na2O |

||

|

3µm-45µm |

>3.90 |

>99.0 |

<0.20 |

<0.10 |

<1.00

|

Alumina Powder Advantages

1. Compare with other tabular powder, the tabular alumina powder has the excellent combination properties. Such as high melting point, strong hardness, high mechanical strength, good wear resistance, chemical resistance, oxidation resistance and heat resistance etc.

2. Flat sheet shape makes the friction bigger, improves grinding speed and efficiency, this can reduce the number of grinding machines, labor and grinding time.

3. Flat sheet shape makes the object grind not easy to scratched, the rate of qualified products can increase 10%-15%. For example, the rate of qualified semiconductor silicon wafer can achieve to 96% or more.

4. Has the double effects of nano and micro powders, the surface activity is moderate, not only can effectively combine with other active groups, but also not easy to agglomerate and facilitate effective dispersion.

5. Has good adhesion, significant shielding effect and ability to reflect light.

6. The tabular alumina powder is almost transparent, colorless, and has a flat and smooth surface. The well-crystallized crystals are regular hexagons.

7. The tabular alumina powder can be made into excellent polishing powder.

1. Electronics industry: grinding and polishing of semiconductor monocrystalline silicon wafers, quartz quartz crystals, compound semiconductors (crystalline gallium, phosphating nano).

2. Glass industry: grinding and processing of crystal, quartz glass, kinescope glass shell screen, optical glass, liquid crystal display (LCD) glass substrate, and quartz crystal.

3. Coating industry: special coatings and fillers for plasma spraying.

4. Metal and ceramic processing industry: precision ceramic materials, sintered ceramic raw materials, high-grade high-temperature coatings, etc.

Your Inquiry

If you have any questions.Please feel free to contact us.