Products

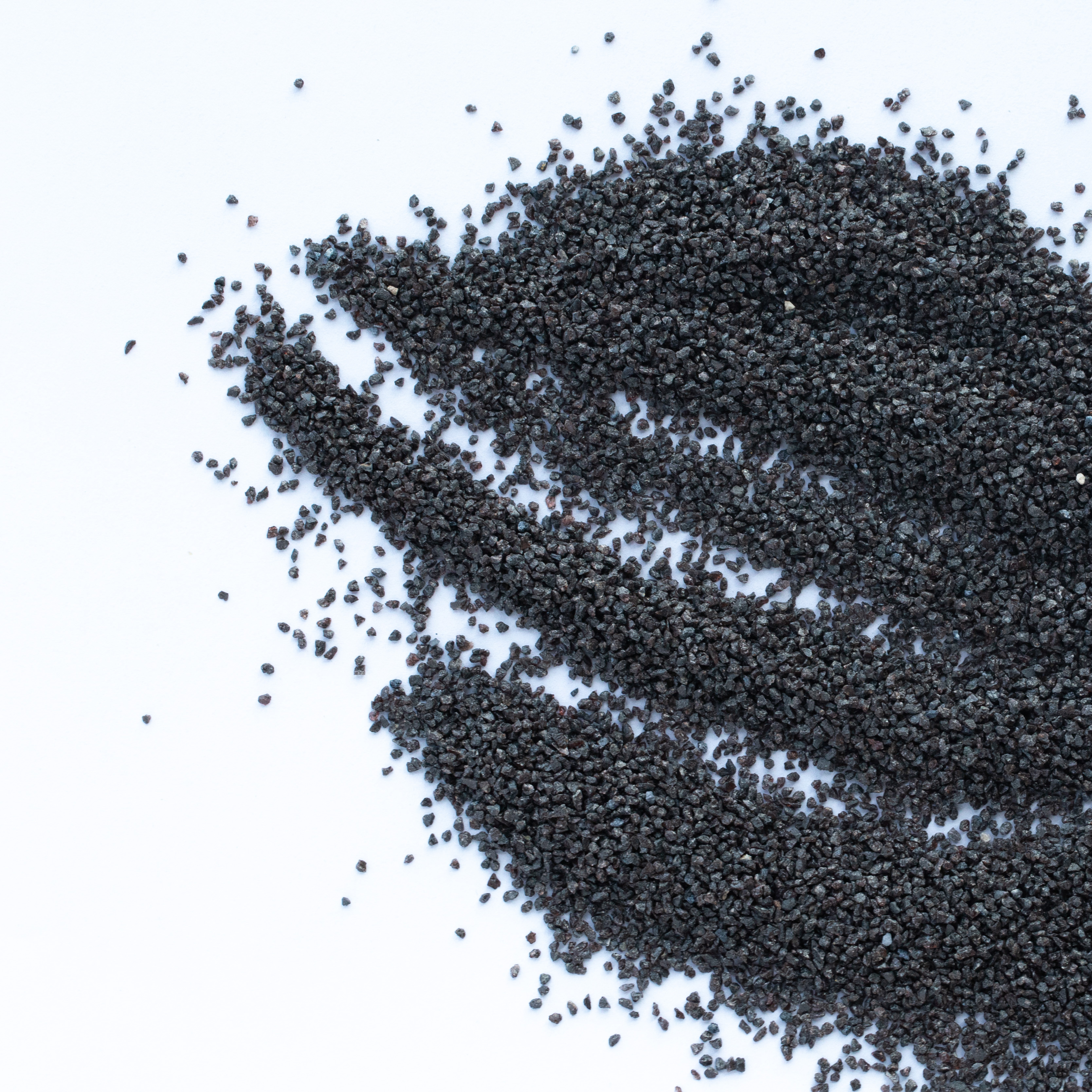

Brown fused alumina grit for sandpaper grinding wheel coated abrasive

Brown fused alumina/Brown corundum, commonly known as emery, is a brown artificial corundum made by melting and reducing three raw materials: bauxite, carbon material and iron filings in an electric arc furnace, hence the name. Its main component is alumina, and the grades are also distinguished by aluminum content. The lower the aluminum content, the lower the hardness. Product particle size is produced according to international standards and national standards, and can be processed according to user requirements. The general particle size is F4~F320, and its chemical composition varies depending on the particle size. The outstanding feature is that the crystal size is small and impact resistant. Because it is processed and broken by a self-grinding machine, the particles are mostly spherical particles. The surface is dry and clean, and it is easy to bond with the binder. Brown fused alumina is made of abrasive grade bauxite as raw material and supplemented with auxiliary materials. It is refined in an electric arc furnace at a high temperature above 2250℃. On this basis, it is refined by a high-strength magnetic separator and its refractoriness is above 1850℃. The brown corundum produced by our company has the characteristics of high purity, good crystallization, strong fluidity, low linear expansion coefficient and corrosion resistance. The product has the characteristics of non-explosion, non-powdering, and non-cracking during the application process, and is often used in abrasives and refractory raw materials industries.

|

Application

|

Specification

|

Main chemical composition%

|

Magnetic substance%

|

||||

|

Al2o3

|

Fe2o3

|

Sio2

|

Tio2

|

||||

|

Abrasives

|

F

|

4#-80#

|

≥95

|

≤0.3

|

≤1.5

|

≤3.0

|

≤0.05

|

|

90#—150#

|

≥94

|

≤0.03

|

|||||

|

180#—240#

|

≥93

|

≤0.3

|

≤1.5

|

≤3.5

|

≤0.02

|

||

|

P

|

8#—80#

|

≥95.0

|

≤0.2

|

≤1.2

|

≤3.0

|

≤0.05

|

|

|

100#—150#

|

≥94.0

|

≤0.3

|

≤1.5

|

≤3.5

|

≤0.03

|

||

|

180#—220#

|

≥93.0

|

≤0.5

|

≤1.8

|

≤4.0

|

≤0.02

|

||

|

W

|

1#-63#

|

≥92.5

|

≤0.3

|

≤1.5

|

≤3.0

|

--------

|

|

|

Refractory

|

Duansha

|

0-1mm

1-3mm 3-5mm 5-8mm 8-12mm |

≥95

|

≤0.3

|

≤1.5

|

≤3.0

|

--------

|

|

25-0mm

10-0mm 50-0mm 30-0mm |

≥95

|

≤0.3

|

≤1.5

|

≤3.0

|

--------

|

||

|

Powder |

180#-0

200#-0 320#-0 |

≥94.5

≥93.5

|

≤0.5

|

≤1.5

|

≤3.5

|

--------

|

|

Abrasives materials: Grinding wheel, abrasive belt, sandpaper, abrasive cloth, cutting piece, sand blasting technology, grinding, wear-resistant floor, water jet cutting, coated abrasives, consolidated abrasives, etc.

Refractory materials: Castable, refractory brick, ramming material, slide plate, nozzle, ladle, lining material. precision casting, etc

Brown corundum is called industrial teeth: mainly used in refractories, grinding wheels, and sandblasting.

1. Used to manufacture advanced refractory materials, castables, refractory bricks, etc.

2. Sandblasting—the abrasive has moderate hardness, high bulk density, no free silica, high specific gravity, and good toughness. It is an ideal “environmentally friendly” sandblasting material. It is widely used in aluminum profiles, copper profiles, glass, and washed jeans. Precision molds and other fields;

3. Free grinding-grinding grade abrasive, applied to free grinding in the fields of picture tube, optical glass, monocrystalline silicon, lens, watch glass, crystal glass, jade, etc. It is a high-grade grinding material commonly used in China;

4. Resin Abrasives-Abrasives with suitable color, good hardness, toughness, suitable particle cross-section type and edge retention, applied to resin abrasives, the effect is ideal;

5. Coated abrasives—abrasives are raw materials for manufacturers such as sandpaper and gauze;

6. Functional filler-mainly used for automotive brake parts, special tires, special construction products and other collars, which can be used as wear-resistant materials such as runways, docks, parking lots, industrial floors, sports venues, etc.;

7. Filter media-a new application field of abrasives. Granular abrasives are used as the bottom media of the filter bed to purify drinking water or wastewater. It is a new type of water filtration material at home and abroad, especially suitable for non-ferrous metal mineral processing: oil drilling mud weighting agent :

8. Hydraulic cutting-uses abrasives as the cutting medium and relies on high-pressure water jets for basic cutting. It is applied to the cutting of oil (natural gas) pipelines, steel and other parts. It is a new, environmentally friendly and safe cutting method.

Your Inquiry

If you have any questions.Please feel free to contact us.