Products

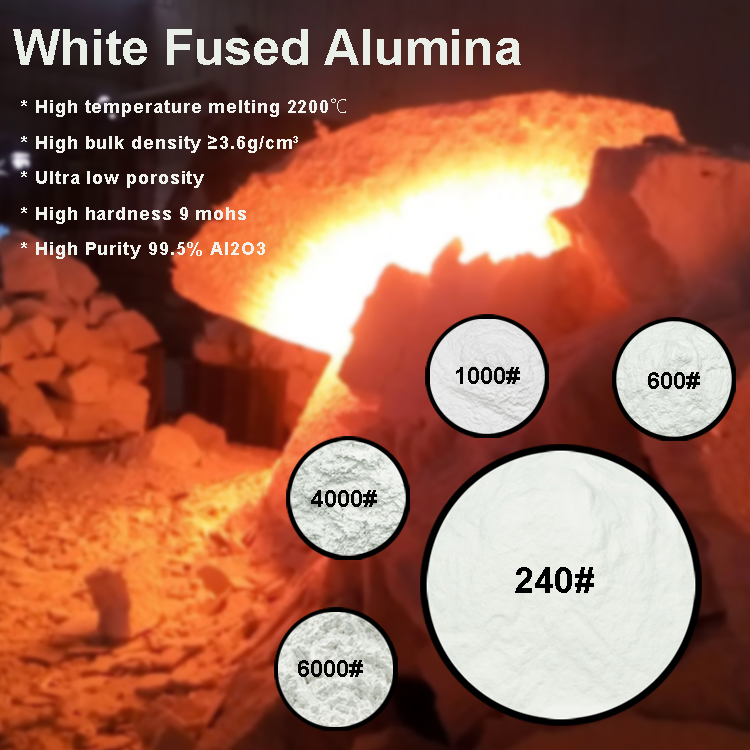

WA White Fused Alumina White Corundum Powder Grinding Blasting Polishing Abrasive Material

White fused alumina abrasive

White corundum is a white abrasive made from industrial alumina powder (Al2O3) with a content of over 98% and a small amount of iron oxide and silicon oxide. It is a white abrasive which is melted at high temperature. Its hardness is slightly higher than that of brown corundum and its toughness is slightly lower. It is made by smelting and cooling above 2000 degrees in arc, grinding and shaping, removing iron by magnetic separation, and sieving into many kinds of granularity. It is compact in texture, high in hardness and sharp in shape.

Chemical compositions

|

Used for abrasive, blasting, grinding,polishing, coating |

|||

|

Properties type |

240#,280#,320#,360#, 400#,500#,600#,700#,800#,1000#,1200#,1500#,2000#,2500#,3000#,4000#,6 0 0 0 #,8 0 0 0 #,1 0 0 0 0 #,12500# | ||

|

Guarantee Value |

Typical Value |

||

|

Chemical composition |

AI2O3 |

99.0 min |

99.5 |

|

SiO2 |

0.2 max |

0.06 |

|

|

Fe2O3 |

0.2 max |

0.04 |

|

|

Na2O |

0.3max |

0.30 |

|

| Test items | indicators |

| Mohs hardness | 9.0 |

| Bulk density | 1.75-1.95g/cm3 |

| Real density | 3.95g/cm3 |

| Melting point | 22500C |

| The highest operating temperature | 19000C |

Advantages of White fused alumina:

1,High hardness and dense particles. Single particle roundness is good.

2, The color is pure white, no impurities, to ensure the wear-resistant layer or wear-resistant paper color and transparency.

3, Uniform distribution of particle size, single particle shape consistent, with a small amount of wear - resistant effect.

4, Chemical stability and acid, alkali no action, high temperature stability is very good.

Application Scenario

1.Used for free grinding, such as glass industry.

2. Used for friction products and wear-resistant floors.

3. Suitable for resin or ceramic bond abrasive, such as grinding wheel, cutting off grinding wheel,etc.

4. Suitable for refractory, wear-resisting and refractory products.

5. Used for polishing, such as grindstone, grinding block, plate turning, etc.

6. Used for coating abrasive tools, such as sandpaper, emery cloth, sand belt, etc.

7. Used for precision casting, grinding, grinding, polishing mold production.

- Used for free grinding, such as glass industry.

2. Used for friction products and wear-resistant floors.

3. Suitable for resin or ceramic bond abrasive, such as grinding wheel, cutting off grinding wheel,etc.

4. Suitable for refractory, wear-resisting and refractory products.

5. Used for polishing, such as grindstone, grinding block, plate turning, etc.

6. Used for coating abrasive tools, such as sandpaper, emery cloth, sand belt, etc.

7. Used for precision casting, grinding, grinding, polishing mold production.

Your Inquiry

If you have any questions.Please feel free to contact us.