Products

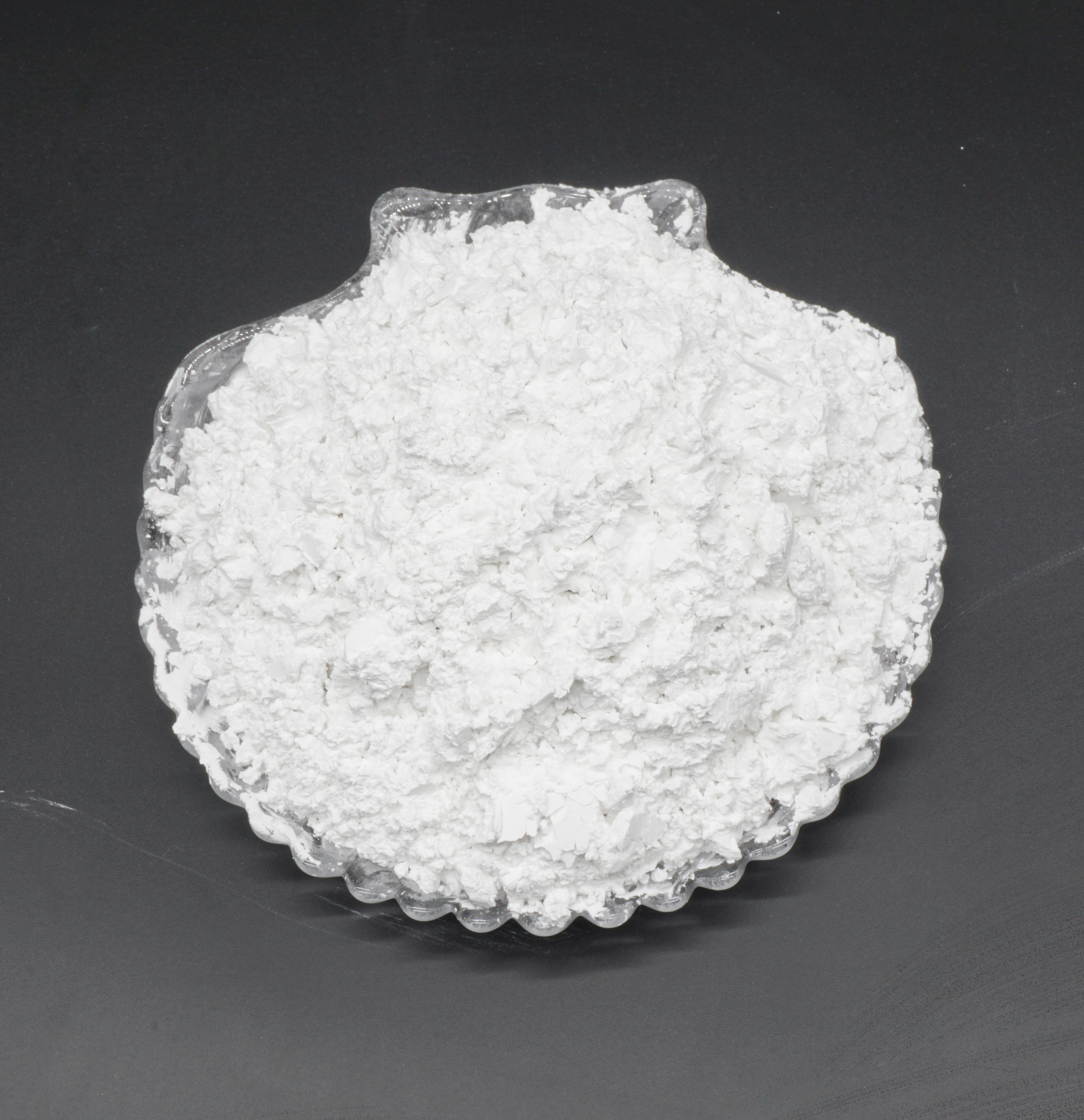

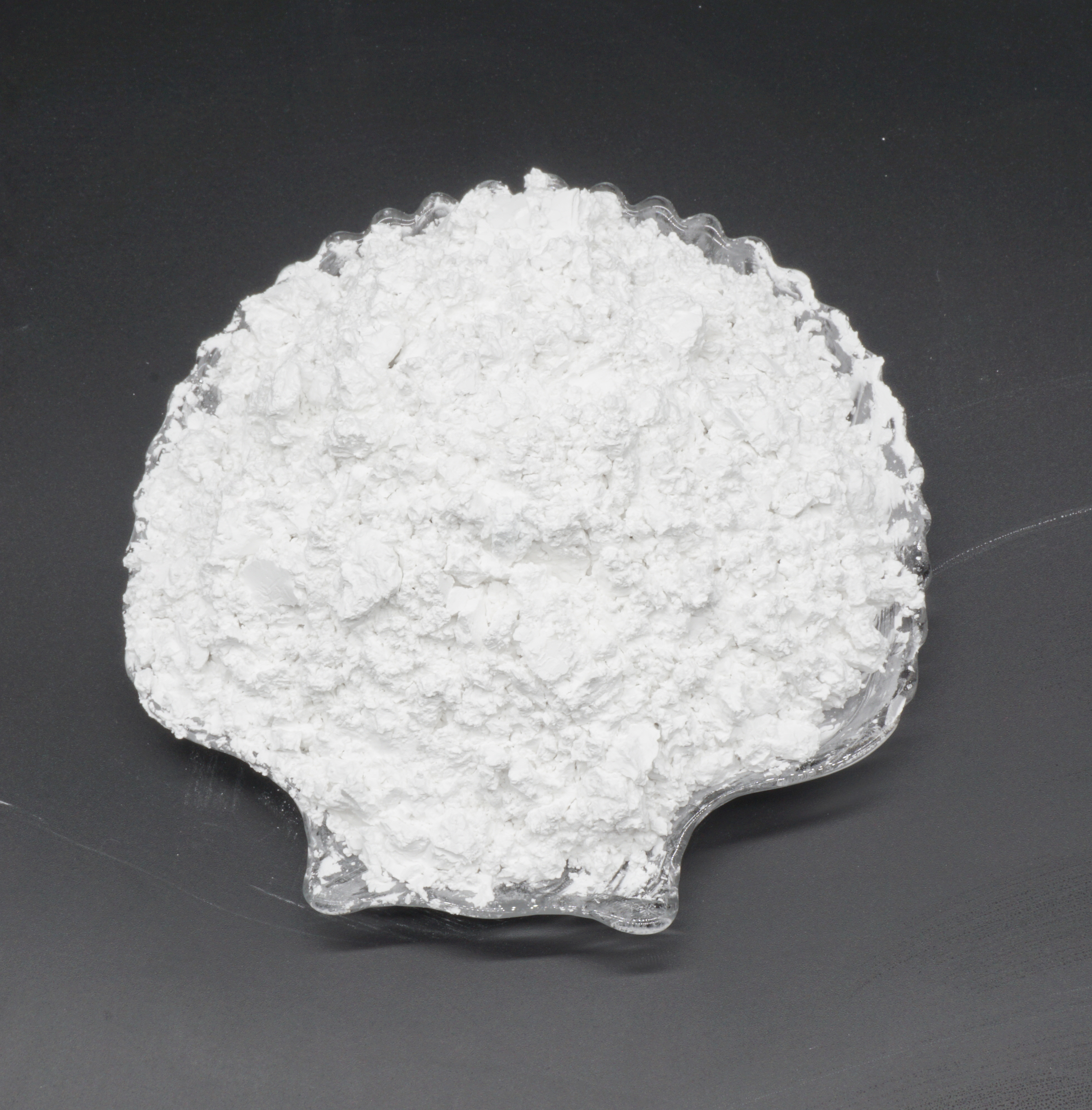

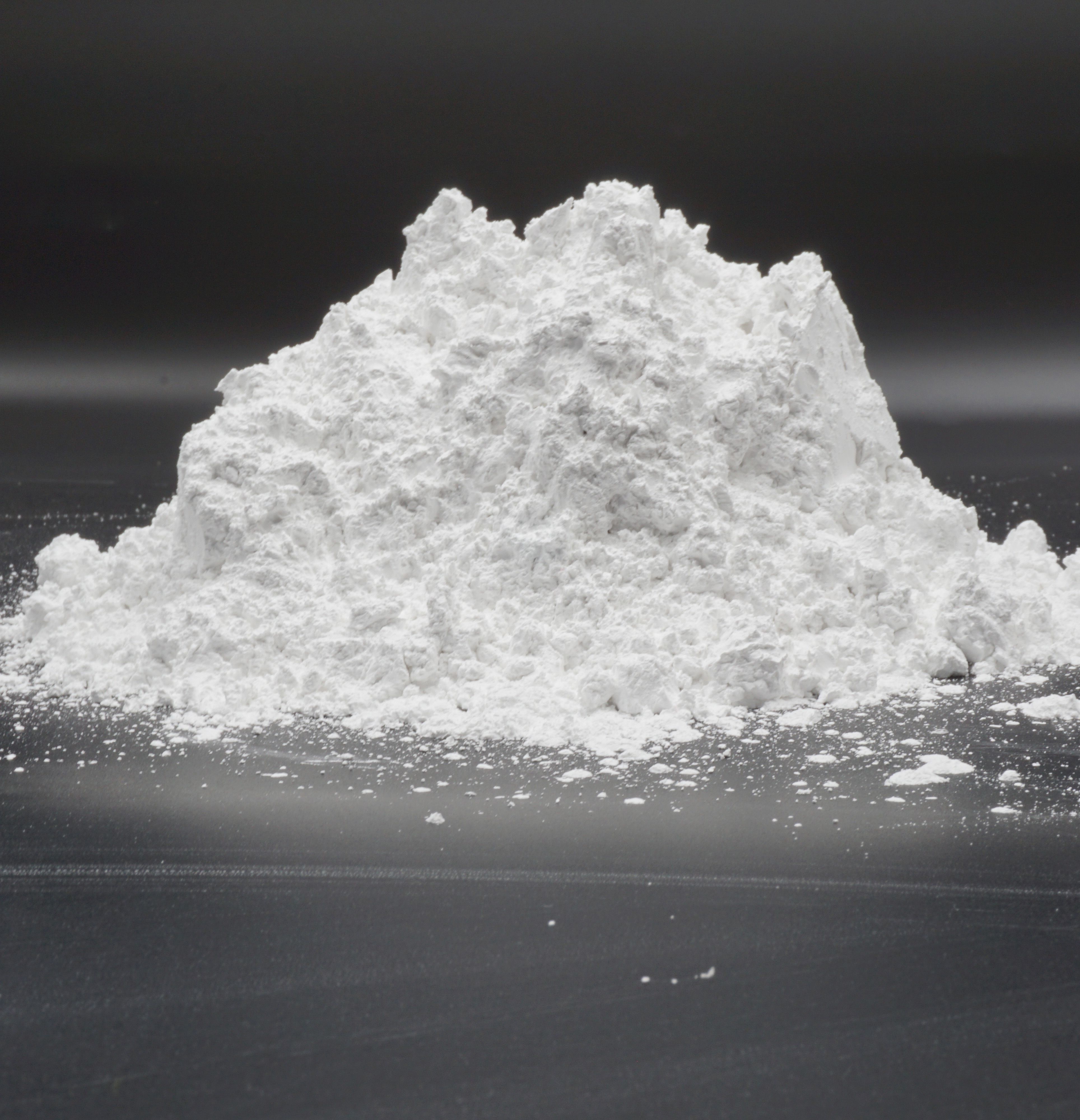

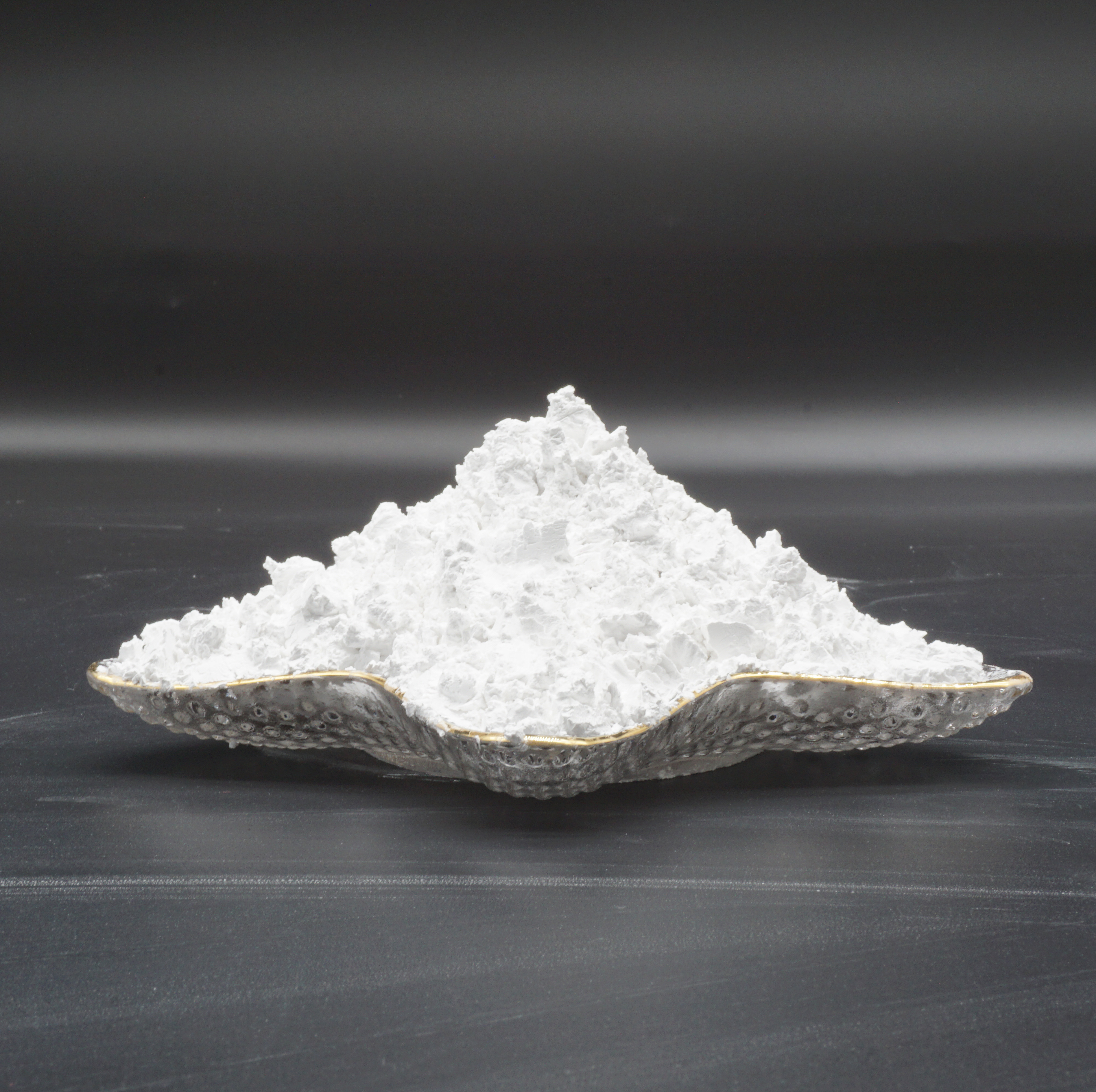

Grinding Blasting Polishing Media 240#-12500# White Fused Alumina Powder

WFA Description

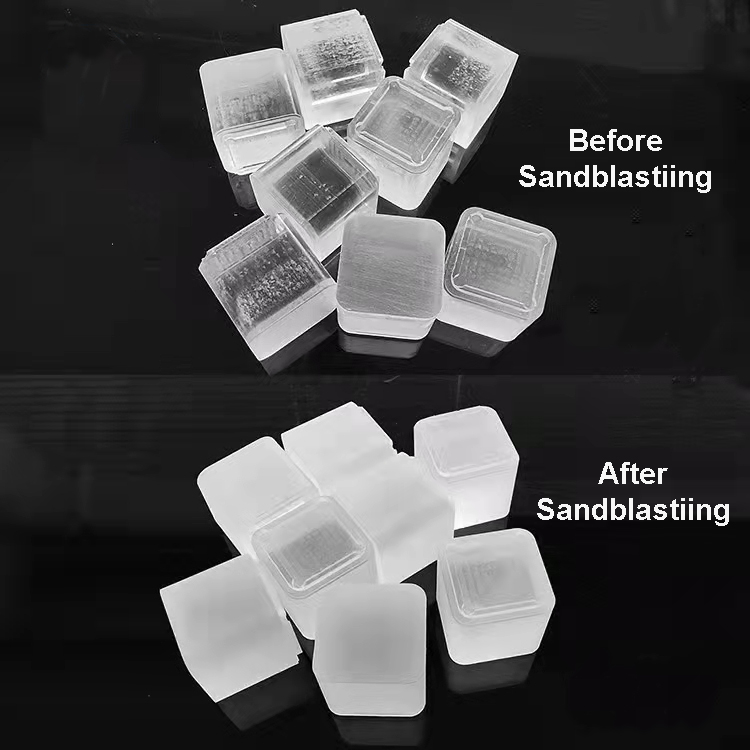

White corundum with industrial alumina powder as raw material, in the arc after 2000 degrees of high temperature melting after cooling, grinding and shaping, magnetic separation to remove iron, screen into a variety of granularity, its dense texture, high hardness, particles form a sharp Angle, suitable for the manufacture of ceramics, resin consolidation abrasive tools and grinding,polishing, sandblasting, precision casting (investment casting special corundum), etc. It can also be used to manufacture high-grade refractory materials

Chemical and Physical Composition

|

MODEL: 240#,280#,320#,360#, 400#,500#,600#,700#,800#,1000#,1200#,1500#,2000#,2500#,3000#,4000#,6 0 0 0 #,8 0 0 0 #,1 0 0 0 0 #,12500# |

|||

|

chamical ananlysis(%) |

physical properties |

||

|

Al2O3 |

≥99.2 |

color |

white |

|

SiO2 |

≤0.04 |

crystal form |

a-Al2O3 |

|

NaO2 |

≤0.22 |

bulk density |

1.75-1.95g/cm3 |

|

Fe2O3 |

≤0.04 |

true density |

3.95-3.97g/cm3 |

|

K2O |

≤0.01 |

mosh hardness |

9.0min |

|

usage |

polishing, blasting, coating, grinding, etc. |

||

WFA Usage

1. Make transparent ceramics: high-pressure sodium lamps, EP-ROM window.

Αlpha-Al2O3 can be sintered into a transparent ceramic to use as a high-pressure sodium lamp material; as well as can be used as a compact fluorescent lamp in the protective layer of the phosphor layer to improve lamp life.

2. As high class polishing materials for: glass, metal, semiconductor materials, plastic, tape, grinding belt, etc.

3. As additive: reinforce paint, rubber, plastic wear-resistant.

As a new composite material, Al2o3 powder can be used as dispersion strengthening and additives, such as adding alumina nanoparticles into rubber, wear resistance can be improved several times.

4. Use as catalyst, catalyst carrier, analytical reagent.

By virtue of its special properties, Al2o3 powder is widely used as catalyst and its carrier, in ceramics and other fields.

5. Use for coating

Alumina nanoparticles as an optical material and surface protective layer of material can absorb ultraviolet light, and in some wavelengths of light excitation can be generated with the particle size of the wavelength of light.

6.Use for High strength ceramic

In ceramic applications, precision ceramics made by nano alumina powder have the similar metal plasticity and toughness, light weight, in particular, greatly enhance the strength.

By adding a small amount of nano-alumina in the conventional ceramic matrix can make the mechanical properties of materials doubled improve the toughness of ceramics to reduce its sintering temperature.

- Used for free grinding, such as glass industry.

2. Used for friction products and wear-resistant floors.

3. Suitable for resin or ceramic bond abrasive, such as grinding wheel, cutting off grinding wheel,etc.

4. Suitable for refractory, wear-resisting and refractory products.

5. Used for polishing, such as grindstone, grinding block, plate turning, etc.

6. Used for coating abrasive tools, such as sandpaper, emery cloth, sand belt, etc.

7. Used for precision casting, grinding, grinding, polishing mold production.

Your Inquiry

If you have any questions.Please feel free to contact us.