Products

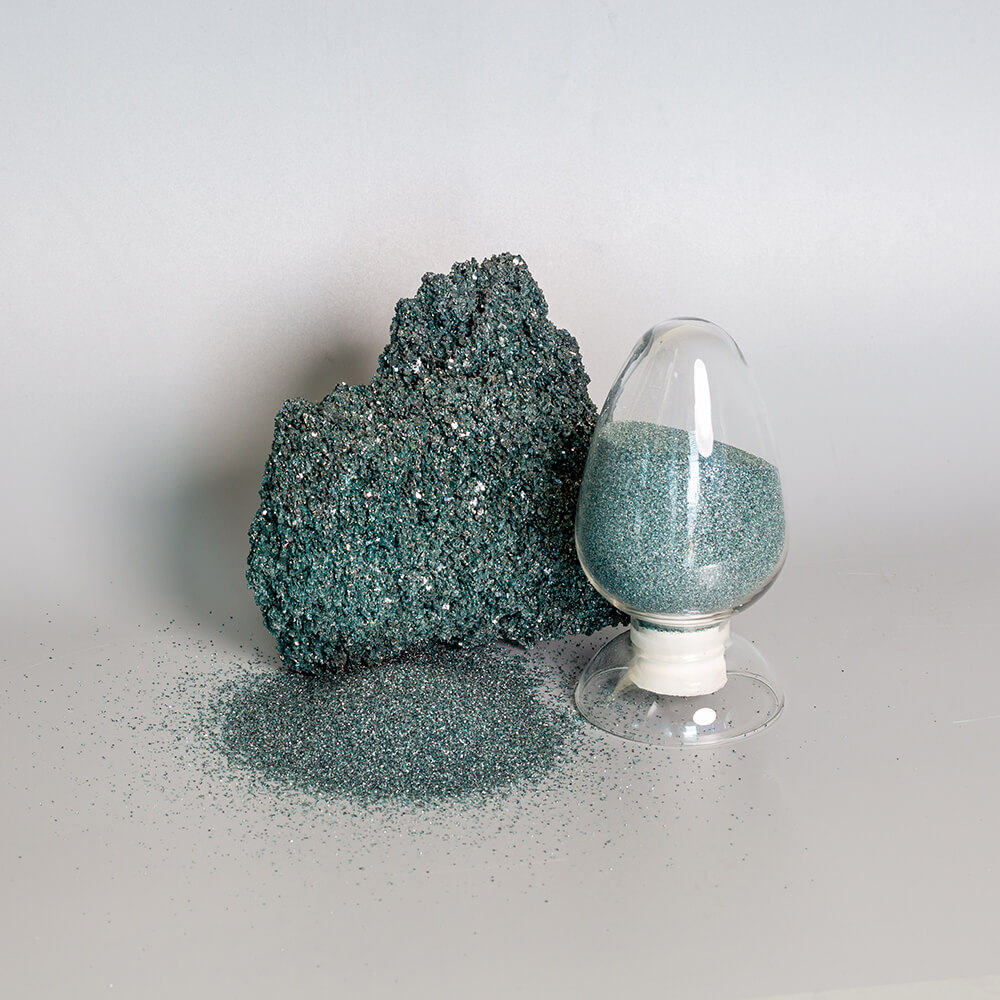

Green Silicon Carbide Powder for Bonded Silicon Carbide Grinding Wheel

Green silicon carbide Description

Green silicon carbide is made of quartz sand and petroleum coke through high-temperature melting. The production method is basically the same as that of black silicon carbide, but the requirements for raw materials are different. The smelted crystals have high purity, high hardness and strong cutting force, and are suitable for processing hard and brittle materials. Green silicon carbide is suitable for grinding hard alloys, hard and brittle metals and non-metallic materials, such as non-ferrous metals such as copper, brass, aluminum and magnesium, and non-metallic materials such as precious stones, optical glass and ceramics.

|

Physic Properties

|

|

|

Color

|

Green

|

|

Crystal form

|

Polygon

|

|

Mohs hardness

|

9.2-9.6

|

|

Micro hardness

|

2840~3320kg/mm²

|

|

Melting point

|

1723

|

|

Maximum operating temperature

|

1600

|

|

True density

|

3.21g/cm³

|

|

Bulk density

|

2.30g/cm³

|

|

Chemical composition

|

|||

|

Grains

|

Chemical composition(%)

|

||

|

Sic

|

F.C.

|

Fe2O3

|

|

|

16#--220#

|

≥99.0

|

≤0.30

|

≤0.20

|

|

240#--2000#

|

≥98.5

|

≤0.50

|

≤0.30

|

|

2500#--4000#

|

≥98.5

|

≤0.80

|

≤0.50

|

|

6000#-12500#

|

≥98.1

|

≤0.60

|

≤0.60

|

1.Abrasive: automotive, aerospace, metalworking, and jewelry. It is used for grinding, cutting, and polishing of hard metals and ceramics.

2.Refractory: furnaces and kilns due to its high thermal conductivity and low thermal expansion.

3.Electronics: LEDs, power devices, and microwave devices due to its excellent electrical conductivity and thermal stability.

4.Solar energy: solar panels

5.Metallurgy

6.Ceramics: cutting tools, wear-resistant parts, and high-tempeature components

Your Inquiry

If you have any questions.Please feel free to contact us.