Products

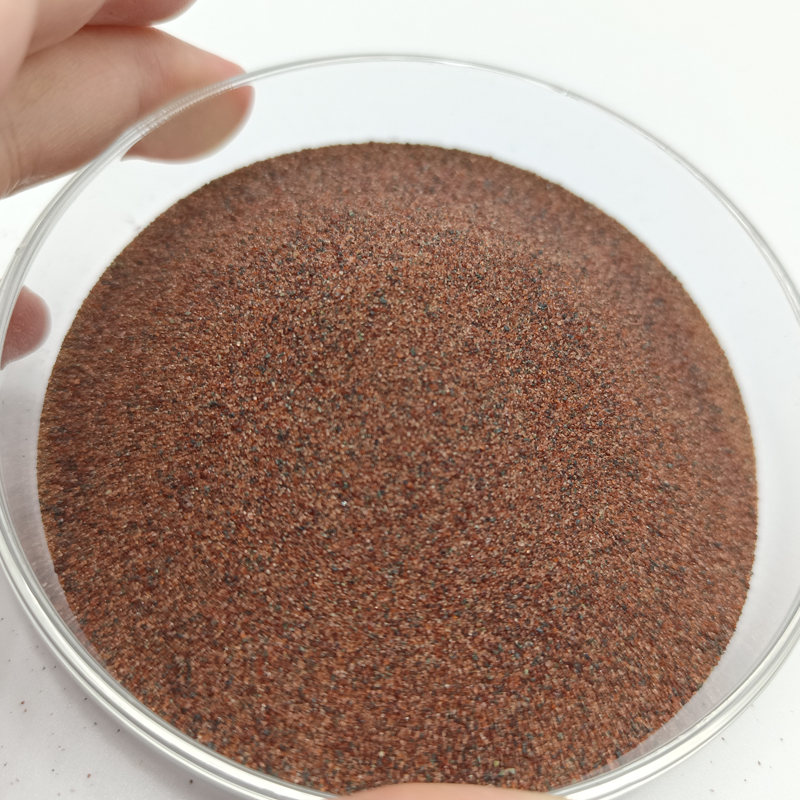

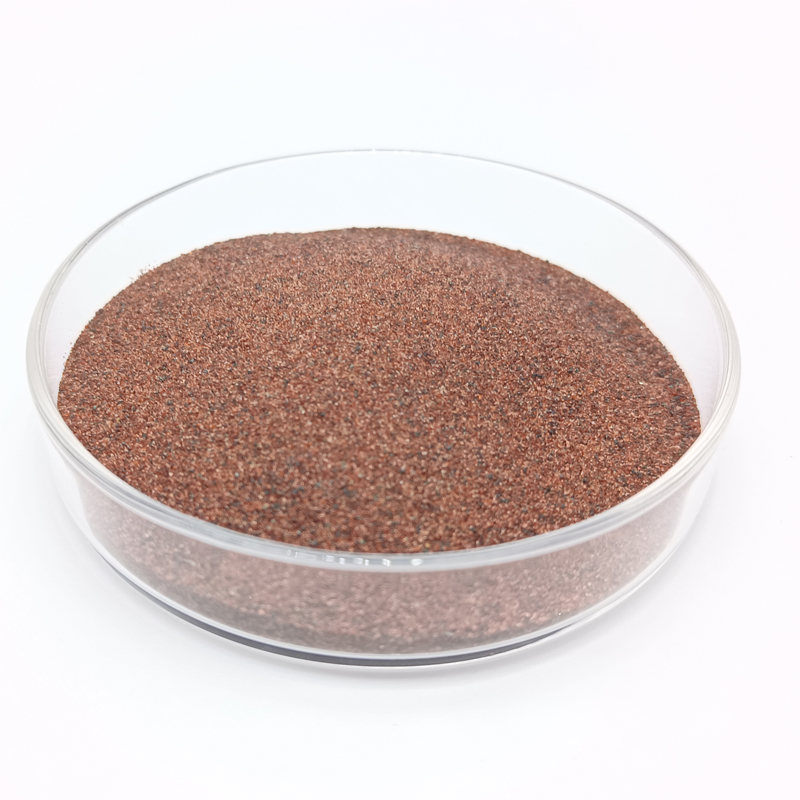

80 Mesh Garnet Sand Abrasives for Waterjet Cutting

Garnet sand

Garnet sand is a good abrasive which is used for water filtration and as a wood finisher for furniture pieces. As an abrasive, garnet sand can be divided into two categories: blasting grade and water jet grade. Garnet sand is crushed into finer grains and used for sand blasting. The larger grains after being crushed are used for faster work while smaller grains can be used for finer finishes. Garnet sand is brittle and can fracture easily – which is the reason why different types of sand are produced.

Garnet sand is also known as water jet cutting sand. It is made from calcium-aluminium silicate and is normally used as a replacement for silica sand in sand blasting operations. There are various types of sandblasting media including mineral abrasives like aluminium oxide and coal slag. Garnet sand is the most popular sandblasting type, but since these types create a significant amount of dust, they are banned in many countries like Germany and Portugal to use as a blasting grit.

Advantages of Our Garnet

+Almandine Rock Garnet

+Great Hardness

+Sharp Edge

+Chemical Stability

+Lower chloride content

+High Melting Point

+Low Dust Generation

+Economical

+Low conductivity

+No Radioactive Components

Garnet Sand Specifications

| Physical properties | Chemical composition | ||

| Specific Gravity | 4.0-4.1 g/cm | Silica Si 02 | 34-38% |

| Bulk Density | 2.3-2.4g/cm | Iron Fe2 O3+FeO | 25-33% |

| Hardness | 7 .5-8.0 | Alumina AL2 O3 | 17-22% |

| Chloride | <25 ppm | Magnesium MgO | 4-6% |

| Acid solubility(HCL) | <1 .0% | Sodium Oxide Cao | 1-9% |

| Conductivity | < 25 ms/m | Manganese MnO | 0-1% |

| Melting point | 1300 °C | Sodium Oxide Na2 O | 0-1% |

| Grain shape | Granule | Titanium oxide Ti 02 | 0-1% |

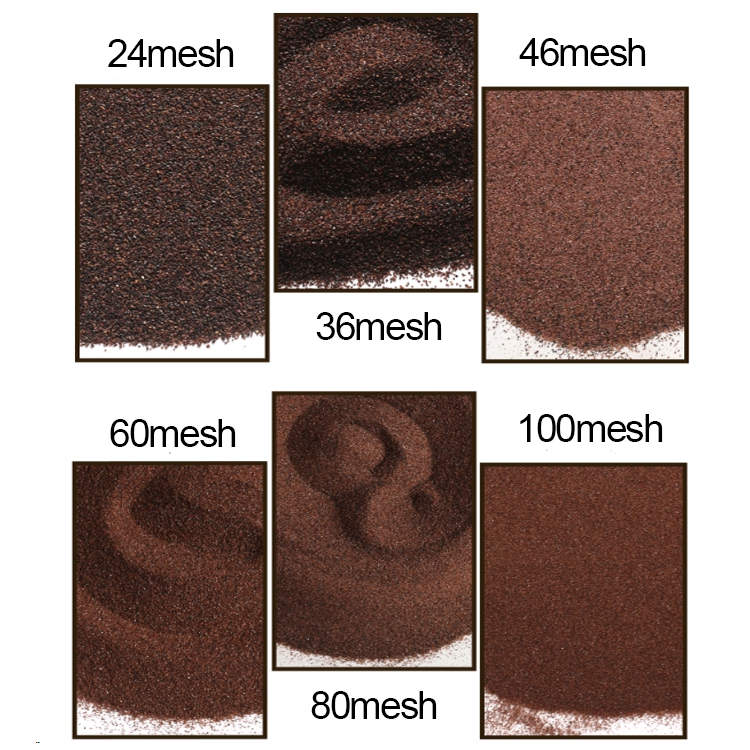

Conventional production size:

Sand blasting/surface treatment:8-14#, 10-20#, 20-40#, 30-60#

Water knife cuts:60#,80#,100#,120#

Water treatment filter material:4-8#, 8-16#, 10-20#

Wear resistant floor sand: 20-40#

Garnet Sand Applications

1) As an abrasive garnet can be broadly divided in two categories, blasting grade and water jet grade. The garnet, as it is mined and collected, is crushed to finer grains; all pieces which are larger than 60 mesh (250 micrometres) are normally used for sand blasting. The pieces between 60 mesh (250 micrometres) and 200 mesh (74 micrometres) are normally used for water jet cutting. The remaining garnet pieces that are finer than 200 mesh (74 micrometres) are used for glass polishing and lapping. Regardless of the application, the larger grain sizes are used for faster work and the smaller ones are used for finer finishes.

2) Garnet sand is a good abrasive, and a common replacement for silica sand in sand blasting. Alluvial garnet grains which are rounder are more suitable for such blasting treatments. Mixed with very high pressure water, garnet is used to cut steel and other materials in water jets. For water jet cutting, garnet extracted from hard rock is suitable since it is more angular in form, therefore more efficient in cutting.

3) Garnet paper is favoured by cabinetmakers for finishing bare wood.

4) Garnet sand is also used for water filtration media.

5) Used in non-skid surfaces and heavily as a semi-precious stone

Your Inquiry

If you have any questions.Please feel free to contact us.