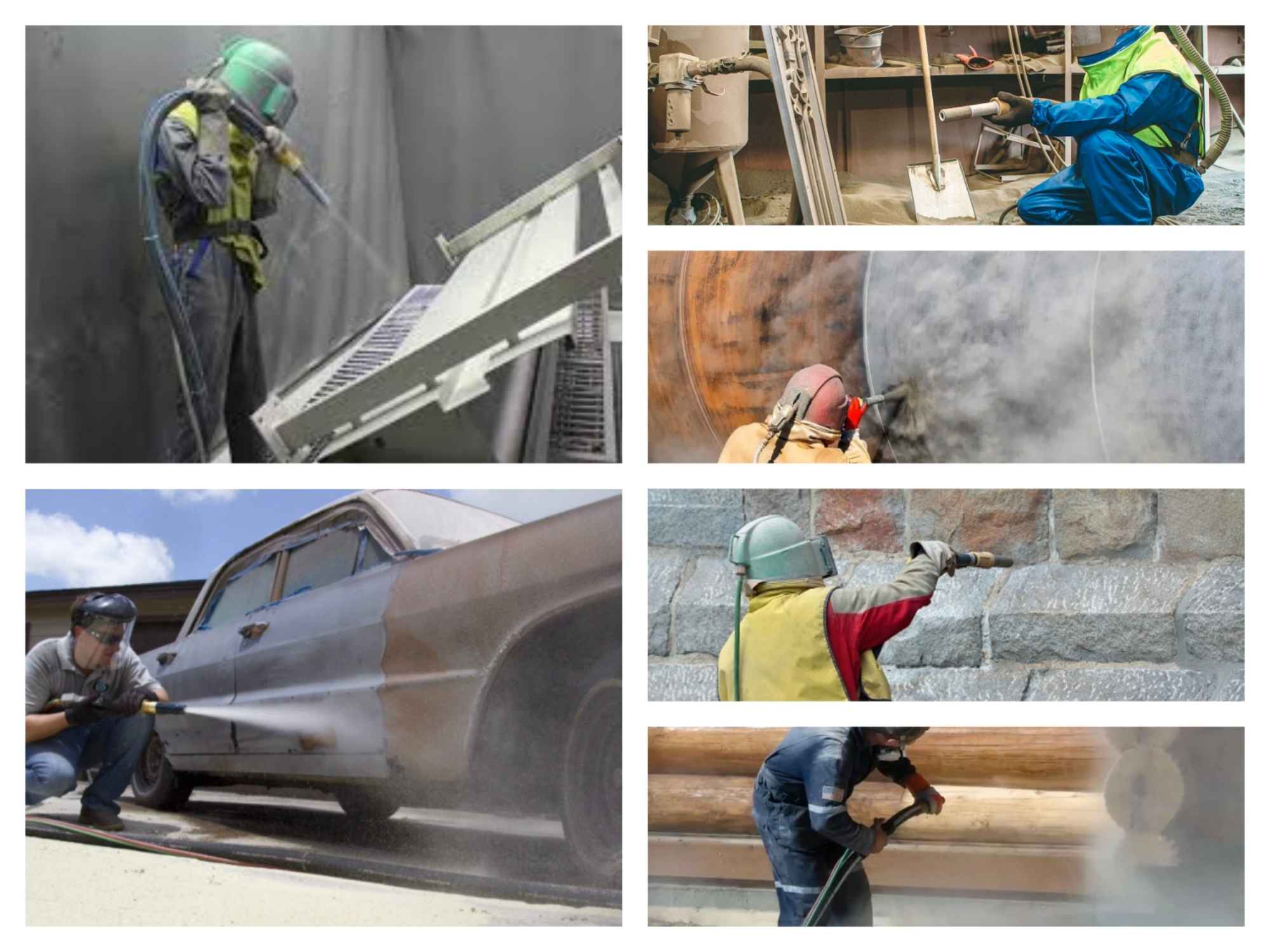

Portable Sandblasting Equipment Drives Changes in Abrasive Market DemandWith the continuous growth of industrial manufacturing and on-site operation needs, portable sandblasting equipment has gradually become an important part of the surface treatment industry. Compared with traditional fixed sandblasting equipment, portable sandblasting equipment has the advantages of small size, light weight, and quick relocation, which has led to its expanding application in various industries, especially playing an irreplaceable role in maintenance, renovation, surface cleaning, and small-batch production. More and more companies are paying attention to the use of portable sandblasting equipment, and the selection of abrasives has become a key factor affecting sandblasting effect, work efficiency, and environmental compliance.

The characteristics of portable sandblasting equipment determine that the requirements for sandblasting abrasives cannot be ignored. Unlike traditional equipment, portable sandblasting equipment usually operates in more complex environments, with limited working space, and even in outdoor or high-altitude operations. Therefore, sandblasting operations must consider not only work efficiency but also the environmental friendliness, recyclability, and compatibility of the abrasive with the equipment. Therefore, choosing the right sandblasting abrasive is crucial for improving work quality and efficiency, reducing operational risks, and minimizing environmental pollution.

Special Requirements for Abrasives in Portable Sandblasting Equipment

Portable sandblasting equipment has many advantages compared to traditional equipment, but it also presents some unique challenges. These are mainly reflected in the following aspects:

Complex operating environment: Portable sandblasting equipment can operate in open-air, enclosed, or confined workspaces, requiring abrasives to adapt to different working conditions and surface materials.

High work efficiency: Since sandblasting operations often need to be completed in a short time, the abrasives used need to have strong cutting power to ensure that stains, rust layers, and coatings can be removed quickly.

Difficulty in dust control: Portable equipment usually generates a significant amount of dust during operation. The selection of abrasives needs to consider their dust generation and fragmentation rate; low-dust, low-fragmentation abrasives are more suitable for this environment.

Difficulty in abrasive recycling: In portable sandblasting equipment, due to site limitations, abrasive recycling is often less convenient than with fixed equipment. Therefore, the durability and recyclability of the abrasive are important considerations. Based on these requirements, the industry has gradually developed a series of abrasive types suitable for portable sandblasting equipment. These abrasives meet the efficiency requirements of sandblasting operations while controlling environmental pollution and minimizing usage costs.

Recommended Sandblasting Abrasive Types:

1. Garnet

Garnet is one of the most commonly used sandblasting abrasives today, widely used in portable sandblasting equipment. Garnet has moderate hardness (7.5-8 Mohs), low fragmentation rate, low dust generation, excellent recyclability, and can be used multiple times, making it suitable for long-term operations. Garnet’s advantages also lie in its environmental friendliness; its low metal content and natural mineral composition make it a more environmentally friendly choice.

In portable sandblasting equipment, garnet is widely used in steel structure rust removal, hull cleaning, rail transit cleaning, and concrete surface repair. It provides uniform roughness, helping to improve the adhesion of subsequent coatings, making it an ideal choice for industrial maintenance.

2. Brown Fused Alumina

Brown fused alumina is a high-hardness abrasive (9 Mohs), suitable for sandblasting operations requiring high cutting force, and can quickly remove thick rust layers and scale. Brown fused alumina generates more dust during sandblasting, so special attention should be paid to ventilation and dust control measures during its use.

Despite the higher fragmentation rate, brown fused alumina is still a very cost-effective sandblasting abrasive, especially suitable for applications requiring rapid cleaning and surface repair of heavy industrial equipment, castings, and automotive parts. It can remove surface contaminants in a short time and give the workpiece a rough surface, laying the foundation for subsequent processing.

3. White Fused Alumina

White fused alumina is similar to brown fused alumina, also having very high hardness, but its purity is higher and it contains fewer impurities, effectively avoiding metal contamination. Therefore, it is very suitable for sandblasting of precision parts, especially in the deoxidation and polishing processes of metal surfaces such as stainless steel and aluminum alloys.

The application range of white fused alumina in portable sandblasting equipment is mainly concentrated in the surface treatment of precision parts, such as automotive parts, aerospace parts, and mold repair. It can provide a fine and uniform surface finish, making it ideal for applications requiring high surface quality.

4. Green Silicon Carbide

Green silicon carbide is an extremely hard abrasive, suitable for applications requiring high-precision surface treatment, such as glass etching and optical material surface treatment. Its sharp particles perform exceptionally well in fine surface repair. Although its range of use is relatively small, green silicon carbide is an irreplaceable preferred abrasive in precision fields.

In portable sandblasting, the application of green silicon carbide is mainly concentrated in high-precision surface treatment fields, especially in high-tech fields such as optics, electronics, and glass processing.

5. Glass Beads

Glass beads are a relatively gentle sandblasting abrasive, commonly used for surface finishing, stress relief, and some light cleaning of metal surfaces. Glass beads do not cause excessive wear on the workpiece surface and can provide a uniform, matte surface finish for metal parts.

In portable sandblasting equipment, glass beads are suitable for surface finishing, stress relief, and sandblasting cleaning of aluminum parts. Due to their lower hardness and lack of metal contamination, glass beads are an ideal sandblasting abrasive choice in some precision industries and electronics industries.

Impact of Wet Blasting Technology on Abrasive Selection

With the gradual increase in environmental protection requirements, wet blasting (dustless blasting) technology is gradually gaining favor. Wet blasting technology can effectively reduce the dust generated during sandblasting, improve the working environment, and enhance operational safety. However, wet blasting technology also has stricter requirements for abrasives, especially in terms of recyclability, cleanliness, and stability.

In wet blasting operations, abrasives such as garnet and glass beads are gradually becoming the preferred choice for wet blasting equipment due to their better recyclability and lower dust generation. Although the cost of wet blasting abrasives is higher, their excellent environmental performance and operational efficiency have given them a place in the increasingly environmentally conscious market.

Future Trends: Segmentation and Functionalization of the Abrasive Market

As the application of portable sandblasting equipment expands globally, the abrasive market is developing towards segmentation and functionalization. In the future, sandblasting abrasives will be more precisely customized according to the needs of specific application fields. The continuous tightening of environmental regulations will drive the development of more environmentally friendly and highly recyclable abrasives. At the same time, the functionality of abrasives will be further enhanced to meet more complex industrial demands.

Industry experts predict that with the continuous development of portable sandblasting technology, the abrasive market will see new growth opportunities, especially in the fields of environmental protection and precision surface treatment. The research and application of innovative abrasives will become a future trend in the industry.