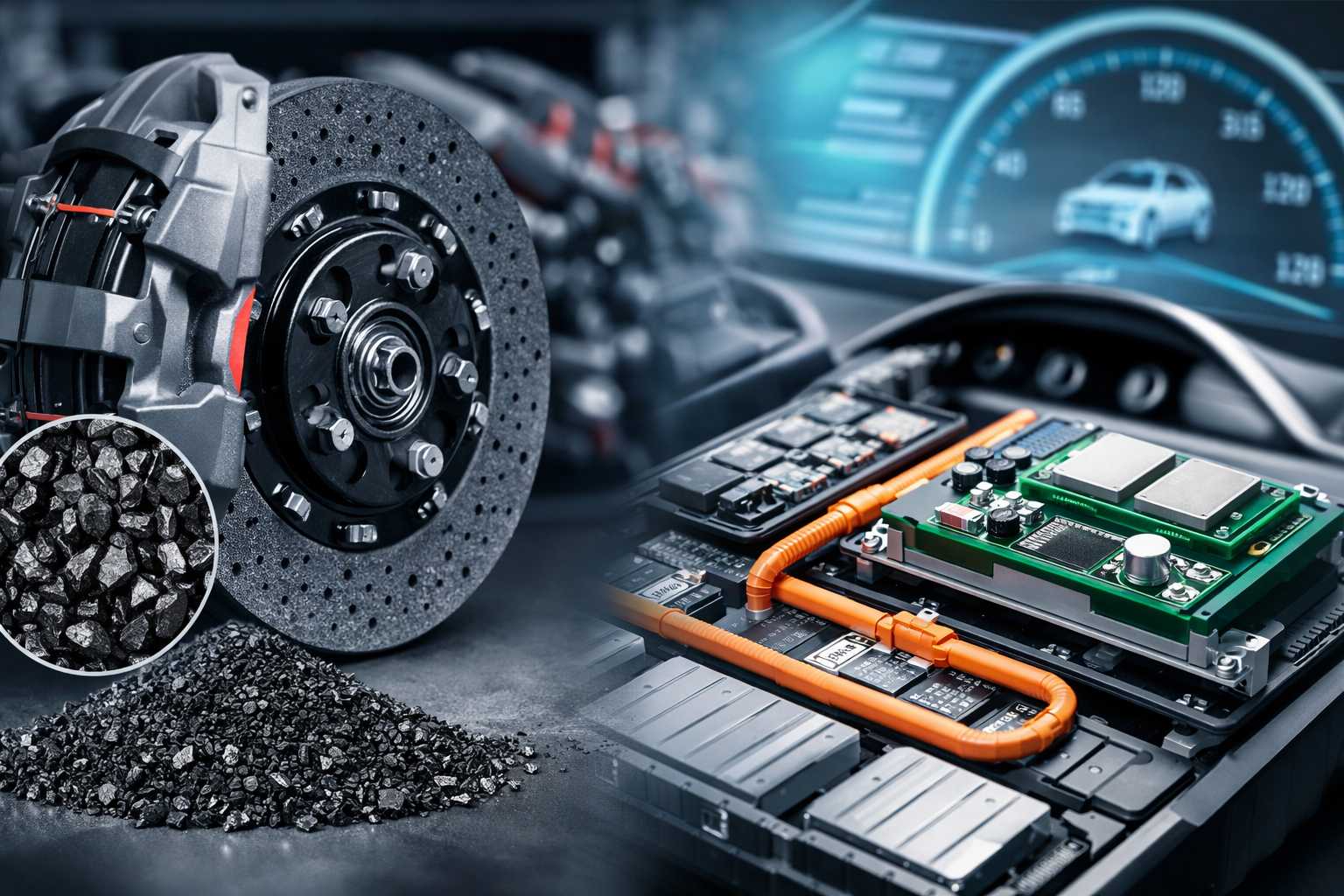

Black silicon carbide (Black SiC) has become one of the most important advanced ceramic and abrasive materials used throughout the modern automotive industry. Thanks to its outstanding hardness, superior wear resistance, high thermal conductivity, excellent chemical inertness, and remarkable stability under extreme temperatures, black silicon carbide plays a vital role not only in traditional internal combustion engine vehicles but also in next-generation electric vehicles (EVs).

From brake systems and engine components to precision grinding, surface treatment, semiconductor substrates, and advanced material research, Black SiC supports both structural manufacturing and high-precision finishing processes. As the automotive sector continues moving toward lightweight design, higher efficiency, and longer service life, demand for durable, heat-resistant, and cost-effective materials has grown rapidly. Black silicon carbide stands out as one of the most reliable solutions.

This article provides a comprehensive overview of the key applications, technical functions, and typical grit sizes of black silicon carbide across different automotive segments.

1. Brake System Components

The brake system is one of the most critical safety systems in any vehicle. Components operate under extreme friction, heavy mechanical load, and temperatures that can exceed 800–1000°C during emergency braking. Under such conditions, traditional metallic materials may suffer from severe wear, thermal cracking, or deformation.

Black silicon carbide significantly enhances brake performance by improving wear resistance, thermal shock resistance, and long-term stability.

Applications

-

Carbon ceramic brake discs (C/SiC composites)

-

Brake pads and friction linings

-

Surface grinding and finishing of brake discs

-

Polishing of cast iron and composite brake parts

-

Brake system refurbishment processes

Functions

Black SiC serves several functions in brake manufacturing:

Reinforcement phase:

When incorporated into carbon ceramic composites, SiC forms a strong ceramic matrix that increases hardness and structural strength.

Wear resistance:

Its Mohs hardness (9.2–9.5) ensures long-lasting friction surfaces and reduced material loss.

Thermal stability:

Maintains mechanical integrity under repeated heating and cooling cycles.

Friction control:

Provides stable friction coefficients, improving braking consistency.

Precision machining:

Used in grinding wheels and finishing tools to achieve tight tolerances and smooth surfaces.

Typical Grit Sizes

-

Reaction / processing: F220 – F1000

-

Grinding & finishing: F24 – F120

-

Fine polishing: F400 – F1200

2. Engine and Powertrain Components

Despite the growth of EVs, internal combustion engines still dominate the global vehicle market. Engine and powertrain parts experience high speeds, heavy loads, continuous friction, and elevated temperatures. Durability and efficiency are critical.

Black silicon carbide improves these components through enhanced surface hardness and reduced friction.

Applications

-

Cylinder liners

-

Piston rings

-

Valve seats

-

Turbocharger parts

-

Ceramic bearings

-

Metal matrix composite reinforcements

Functions

Surface strengthening:

SiC particles embedded into coatings or composites improve hardness and minimize wear.

Friction reduction:

Lower friction reduces energy loss and improves fuel efficiency.

Thermal resistance:

Maintains stability at temperatures exceeding 1000°C.

Extended lifespan:

Reduces maintenance intervals and replacement costs.

Precision lapping & honing:

Used as abrasive powders for ultra-fine surface finishing.

Typical Grit Sizes

-

Structural ceramics: F320 – F1500

-

Lapping & honing: F600 – F2000

3. Electric Vehicle (EV) Components

With rapid electrification, the role of silicon carbide has expanded dramatically. SiC-based materials are now essential in EV power electronics and thermal management systems.

Black silicon carbide is widely used for processing ceramic parts and producing high-performance substrates.

Applications

-

SiC ceramic substrates

-

Inverters and power modules

-

Heat sinks

-

Battery cooling plates

-

Insulation components

Functions

High thermal conductivity:

Efficient heat dissipation improves battery life and system reliability.

Electrical insulation:

Prevents short circuits in high-voltage systems.

Lightweight strength:

Supports lightweight vehicle design.

Corrosion resistance:

Stable in coolant and chemical environments.

Precision ceramic processing:

Ensures smooth and defect-free surfaces.

Typical Grit Sizes

-

Ceramic processing: F400 – F2000

-

Micropowders: D3 – D50

4. Automotive Manufacturing & Machining

In addition to functional components, black silicon carbide is extensively used during manufacturing and finishing operations. Its sharp crystal structure provides aggressive cutting ability and high removal rates.

Applications

-

Grinding wheels

-

Sanding belts

-

Shot blasting

-

Surface cleaning

-

Mold polishing

-

Rust removal

-

Deburring

Functions

High-efficiency cutting:

Sharp edges enable fast stock removal.

Surface preparation:

Improves coating adhesion.

Consistent finish quality:

Uniform grit size ensures smooth surfaces.

Cost efficiency:

More economical than green SiC for many processes.

Durability:

Long tool life reduces downtime.

Typical Grit Sizes

-

Grinding: F16 – F80

-

Sandblasting: F24 – F60

-

Polishing: F120 – F600

5. R&D and Advanced Materials Testing

Automotive manufacturers constantly develop new materials to enhance safety and efficiency. Black silicon carbide plays an important role in laboratory testing and research.

Applications

-

Tribology tests

-

Wear simulation

-

Microstructure analysis

-

Surface roughness studies

-

Material formulation development

Functions

Controlled abrasive behavior:

Provides consistent test conditions.

Reliable performance evaluation:

Measures friction and wear accurately.

Supports innovation:

Helps optimize new composites and coatings.

Typical Grit Sizes

-

Lab testing: F400 – F1500

-

Micropowders: D5 – D40

6. Advantages of Black Silicon Carbide Over Other Abrasives

Compared with aluminum oxide, garnet, or green silicon carbide, black SiC offers several advantages:

-

Higher hardness

-

Better thermal stability

-

Faster cutting performance

-

Longer service life

-

Lower cost than green SiC

-

Excellent chemical resistance

-

Suitable for both metal and ceramic processing

These benefits make it an ideal choice for large-scale automotive manufacturing.

7. Industry Trends and Market Outlook

As the automotive industry evolves, several trends are driving increased consumption of black silicon carbide:

-

Lightweight vehicle design

-

EV power electronics growth

-

Increased use of ceramic composites

-

Automation and precision machining

-

Higher durability standards

-

Reduced maintenance costs

With global EV adoption accelerating and advanced braking technologies becoming standard, demand for SiC-based materials is expected to grow significantly in the coming decade.

Manufacturers capable of supplying stable quality, consistent particle size distribution, and customized grit ranges will have strong competitive advantages.

Conclusion

Black silicon carbide has become a critical enabling material throughout the automotive value chain. From high-performance brake systems and durable engine parts to EV power modules and precision manufacturing processes, its exceptional hardness, wear resistance, and thermal stability provide reliable performance under extreme conditions.

With a wide range of grit sizes—from coarse blasting media to ultra-fine micropowders—black SiC supports both heavy-duty machining and ultra-precision finishing. As automotive technology advances toward higher efficiency, electrification, and longer service life, black silicon carbide will continue to play an increasingly important role in shaping the future of mobility.