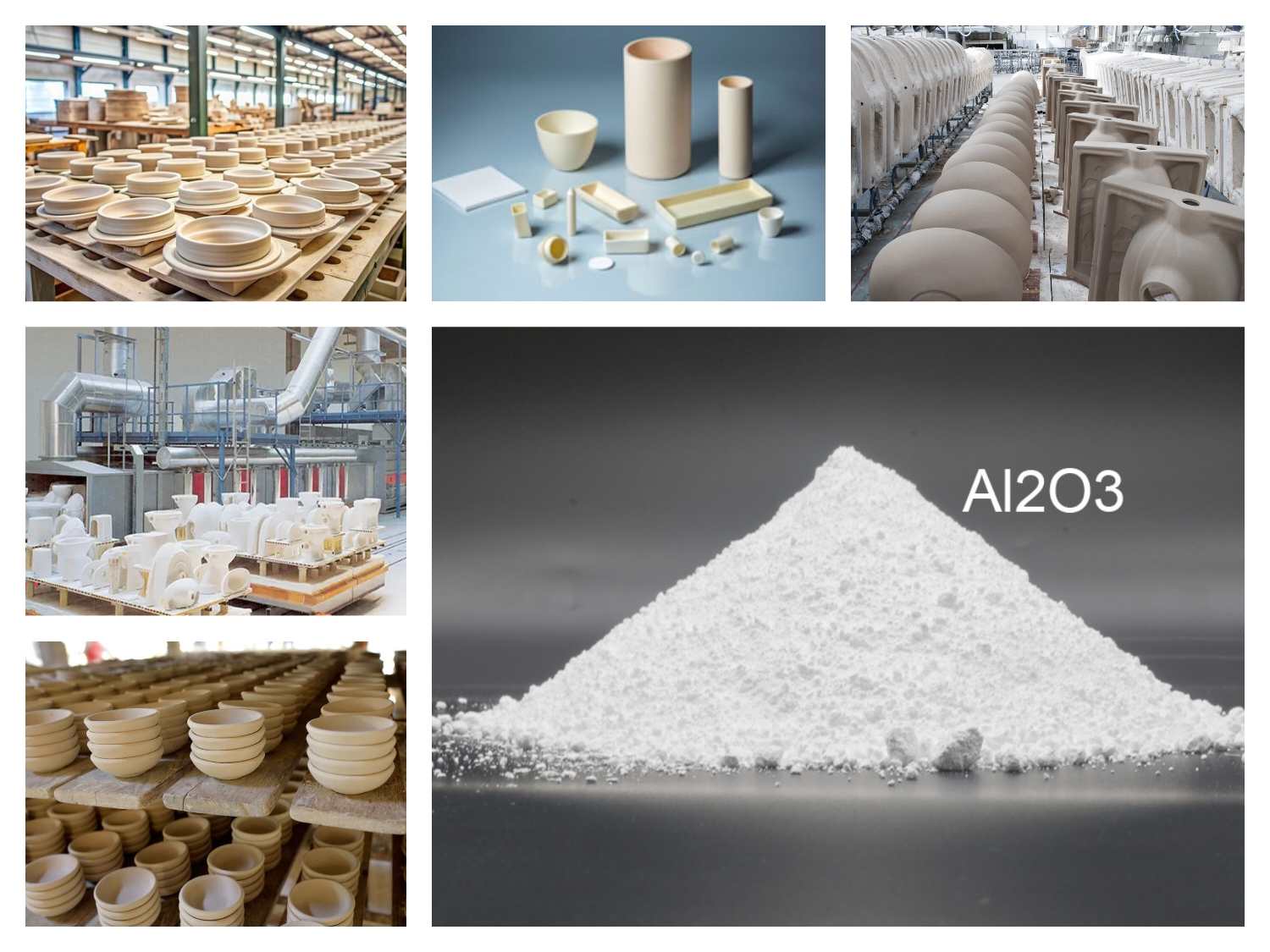

In recent years, as the ceramics industry has expanded from traditional tableware and building materials to high-performance structural ceramics and functional ceramics, the selection and optimization of powder raw materials have become crucial for industrial upgrading. As one of the most widely used important raw materials in the modern ceramics industry, alumina powder (Al₂O₃) is entering the manufacturing system of high-value-added ceramics with higher purity, finer particle size, and more stable crystal phase characteristics, providing fundamental support for the mechanical, electrical, and corrosion resistance properties of ceramic products.

Ⅰ. Characteristics and Classification System of Alumina Powder

Alumina powder is generally classified according to purity, crystal form (α-phase or γ-phase), particle size distribution, sphericity, and sintering characteristics. Alumina powder used in traditional ceramics mainly focuses on ordinary purity and larger particle sizes, while the powders used in structural ceramics and electronic ceramics tend to be high-purity, ultra-fine or sub-micron grade, and more often use the α-alumina crystal phase to ensure the crystal grain stability and strength of the ceramic body during high-temperature sintering.

Particle size distribution is considered one of the key parameters determining ceramic performance. Too coarse a particle size leads to insufficient density in the ceramic body, while too fine a particle size can easily cause uneven grain growth or pore defects during sintering. In the field of electronic ceramics and advanced structural ceramics, stricter D50 and D90 particle size control, as well as narrow particle size distribution, have become an inevitable trend in industry development.

Ⅱ. Expanded Applications in Structural Ceramics

Alumina powder is the most mature ceramic raw material in the field of structural ceramics, possessing characteristics such as high strength, high hardness, wear resistance, corrosion resistance, and high-temperature resistance. Typical applications include bearings, nozzles, guide rollers, mechanical seals, valve bodies, wear-resistant liners, and cutting tools. With the increasing demand for wear-resistant materials in the manufacturing and equipment industries, the market for alumina structural ceramics is steadily expanding, especially in metal mining, coal chemical industry, and precision machining, where the substitution effect of alumina ceramics is significant.

Currently, high purity and density are core indicators of industry focus. In high-temperature sintering, the higher the purity of the powder, the more uniform the crystal grain growth, and the higher the product strength and fracture toughness, thus improving the overall wear life and stability. Meanwhile, the use of spherical alumina powder and submicron powders in the field of structural ceramics is increasing, thanks to their excellent flowability and sintering consistency.

Ⅲ. Technological Value in Electronic and Electrical Ceramics

Electronic ceramics are one of the downstream fields with the greatest incremental potential for alumina powder. Alumina ceramics have excellent insulation and dielectric properties, making them suitable for integrated circuit packaging substrates, high-frequency insulators, heat dissipation substrates, and power insulation components. The rapid development of power electronics and high-frequency communication has driven the continuous optimization of dielectric loss and thermal conductivity of ceramic substrate materials. High-purity alumina ceramic substrates have become an indispensable material in power modules and semiconductor fields.

In the field of LED heat dissipation substrates, ceramic substrates made from alumina powder have good thermal conductivity and electrical insulation properties, providing reliable support for high-power LED packaging. With the large-scale production of new energy vehicles, charging piles, and energy storage equipment, the demand for ceramic substrate materials for power devices has entered a growth cycle, bringing stable and long-term market opportunities for alumina powder.

Ⅳ. Traditional Advantages in Refractory and Catalytic Ceramics

Traditional refractory materials remain an important application area for alumina powder. Due to its high melting point and strong chemical corrosion resistance, alumina powder can be used to manufacture high-temperature furnace linings, crucibles, nozzle bricks, and molten metal contact components. High-temperature industries such as steel, non-ferrous metals, and integrated circuit wafer manufacturing are still the main users of alumina refractory ceramics.

Another mature field is catalytic carrier ceramics, such as honeycomb ceramics and alumina catalytic carriers. The specific surface area and porous structure of alumina powder provide a good adhesion base for catalytic active components, and are widely used in automotive exhaust treatment, refinery catalytic cracking, and environmental denitrification systems.

Ⅴ. Process Route Upgrades and Industrial Technology Pathways

With the technological upgrading of the ceramic industry, alumina powder manufacturers are evolving from traditional chemical precipitation methods to spray drying, isostatic pressing, thermal plasma spheroidization, and surface modification technologies. On the one hand, finer particle sizes and higher purity powders continuously improve sintering performance; on the other hand, modification technologies improve the compatibility of the powder with binders and solvent systems, facilitating rheological control of ceramic slurries and injection molding. It is worth noting that in recent years, the demand for mechanical processing in the ceramics industry has increased simultaneously. The improvement in the precision of ceramic surface processing has led to more regular powder particle morphology, and spherical alumina powder has entered the fields of optical polishing and wafer fabrication, bringing new profit growth points for powder companies.

Ⅵ. Industry Trends: Material Upgrades Drive Changes in Market Landscape

Driven by the material trends of “lightweighting, high performance, and electronization,” high-performance ceramics are gaining a higher strategic position. The technological roadmaps of the automotive, medical, energy, and semiconductor industries determine the future application direction of alumina powder.

Current industry trends show three main characteristics:

① High-temperature equipment and the new energy industry are expanding the demand for wear-resistant and insulating ceramics;

② Electronic ceramics are becoming a source of increased demand for high-purity powders;

③ Particle size refinement, purity improvement, and crystal phase stability are becoming the core of powder competition.

The global ceramic industry chain is currently in a layered competitive landscape. High-end powder companies hold a technological advantage in the electronics and semiconductor fields, while mid-range powders still mainly target structural ceramics and refractory materials. Driven by downstream demand, the mid-to-high-end powder market is expected to maintain growth.

Ⅶ. Conclusion

The trend of the ceramic industry moving from traditional demand to advanced manufacturing is very clear. With the continuous expansion of material technology, preparation processes, and application scenarios, alumina powder will play an even more crucial role in the future ceramic industry. Whether it is structural ceramics, electronic ceramics, thermal management ceramics, or catalytic ceramics, alumina powder materials are becoming an important driving force for the upgrading of the entire ceramic industry chain.