Products

Glass Bead Abrasive

Glass Beads

Glass beads are a spherical, iron-free blasting medium. Taking hardened spherical soda lime glass as raw materials, glass beads are a multi-faceted and commonly used media. Micro glass beads are one of the most common reusable blasting media, which is ideal for non-aggressive cleaning and for producing visually attractive surfaces.

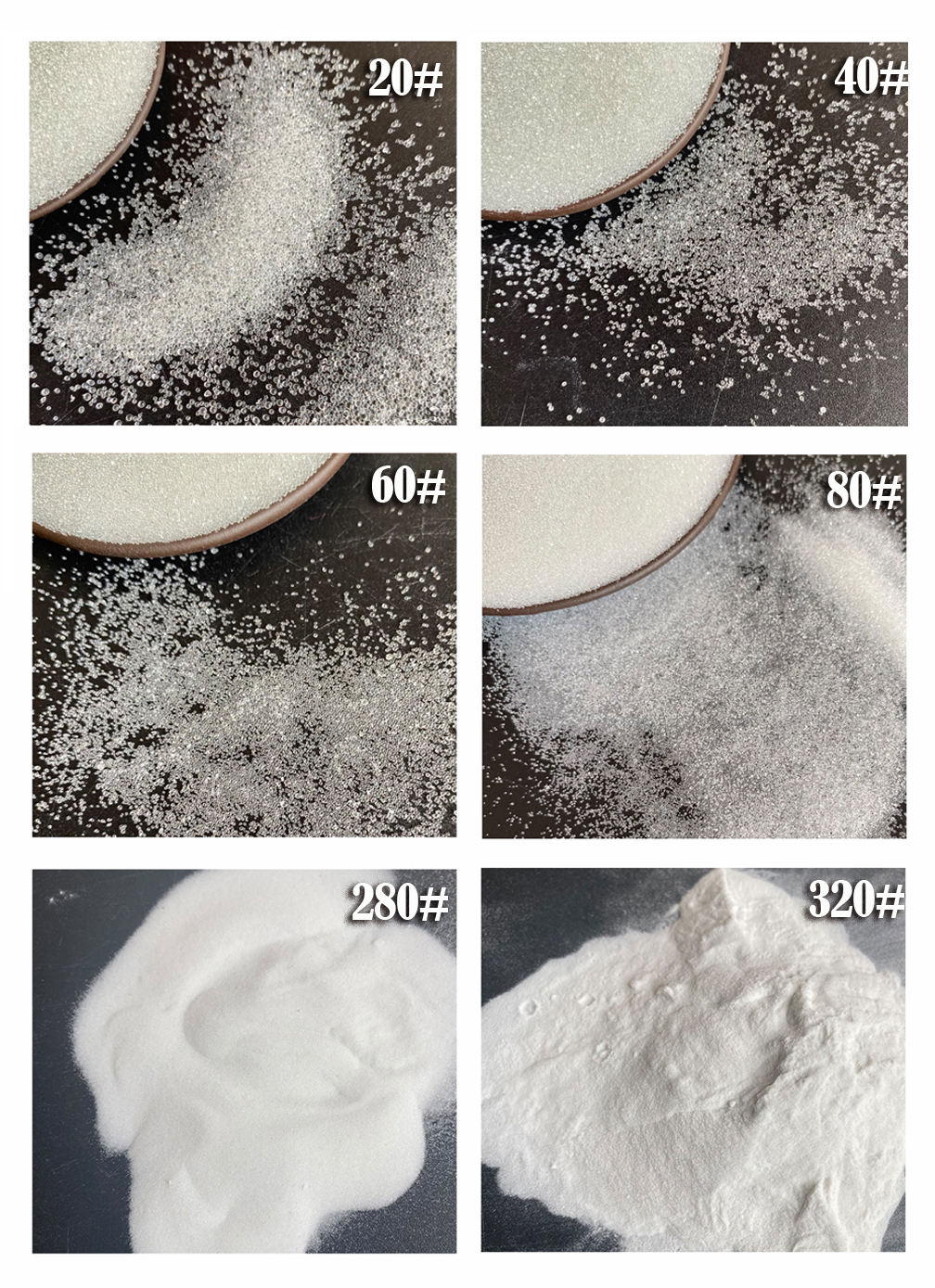

Glass Beads Specifications

| Application | Available Sizes |

| Sandblasting | 20# 30# 40# 40# 60# 70# 80# 90# 120# 140# 150# 170# 180# 200# 220# 240# 325# |

| Grinding | 0.8-1mm 1-1.5mm 1.5-2mm 2-2.5mm 2.5-3mm 3.5-4mm 4-4.5mm 4-5mm 5-6mm 6-7mm |

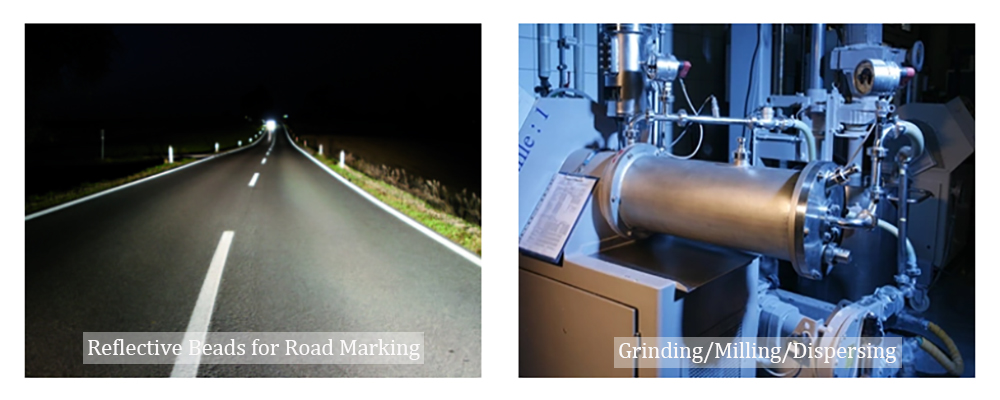

| Road marking | 30-80 mesh 20-40 mesh BS6088A BS6088B |

Glass Beads Chemical Composition

| SiO2 | ≥65.0% |

| Na2O | ≤14.0% |

| CaO | ≤8.0% |

| MgO | ≤2.5% |

| Al2O3 | 0.5-2.0% |

| K2O | ≤1.50% |

| Fe2O3 | ≥0.15% |

Glass Beads Advantages:

-Does not cause dimensional change to the base material

-Environmentally friendlier than chemical treatments

-Leave even, spherical impressions on blasted part surface

-Low breakdown rate

-Lower disposal & maintenance costs

-Soda Lime glass does not release toxins (no free silica)

-Suitable for pressure, suction, wet and dry blasting equipment

-Will not contaminate or leave residue on work pieces

Glass Beads Application

-Blast-cleaning–removing rust and scale from metallic surfaces, removing mould residues from casting and removing tempering colour

-Surface finishing–finishing surfaces to achieve specific visual effects

-Used as disperser, grinding media and filter material in day, paint, ink and chemical industry

-Road marking

Your Inquiry

If you have any questions.Please feel free to contact us.