In modern industry, surface treatment technology plays a crucial role. Sandblasting, as a highly efficient surface cleaning and processing technology, is widely used in the surface treatment of various materials such as metals, glass, ceramics, and plastics. In recent years, with the continuous advancement of technology, the combination of sandblasting guns and abrasives has become a standard configuration in many manufacturing industries, especially in aerospace, automotive manufacturing, optics, and construction.

The combination of sandblasting guns and abrasives has become one of the core technologies in modern industrial manufacturing. Sandblasting guns accelerate abrasives to high speeds using high-pressure air, utilizing the impact force of the abrasives to clean surfaces or perform precision processing. As the demands for processing accuracy and efficiency increase, technological innovation in sandblasting guns and abrasives has become crucial for industry development.

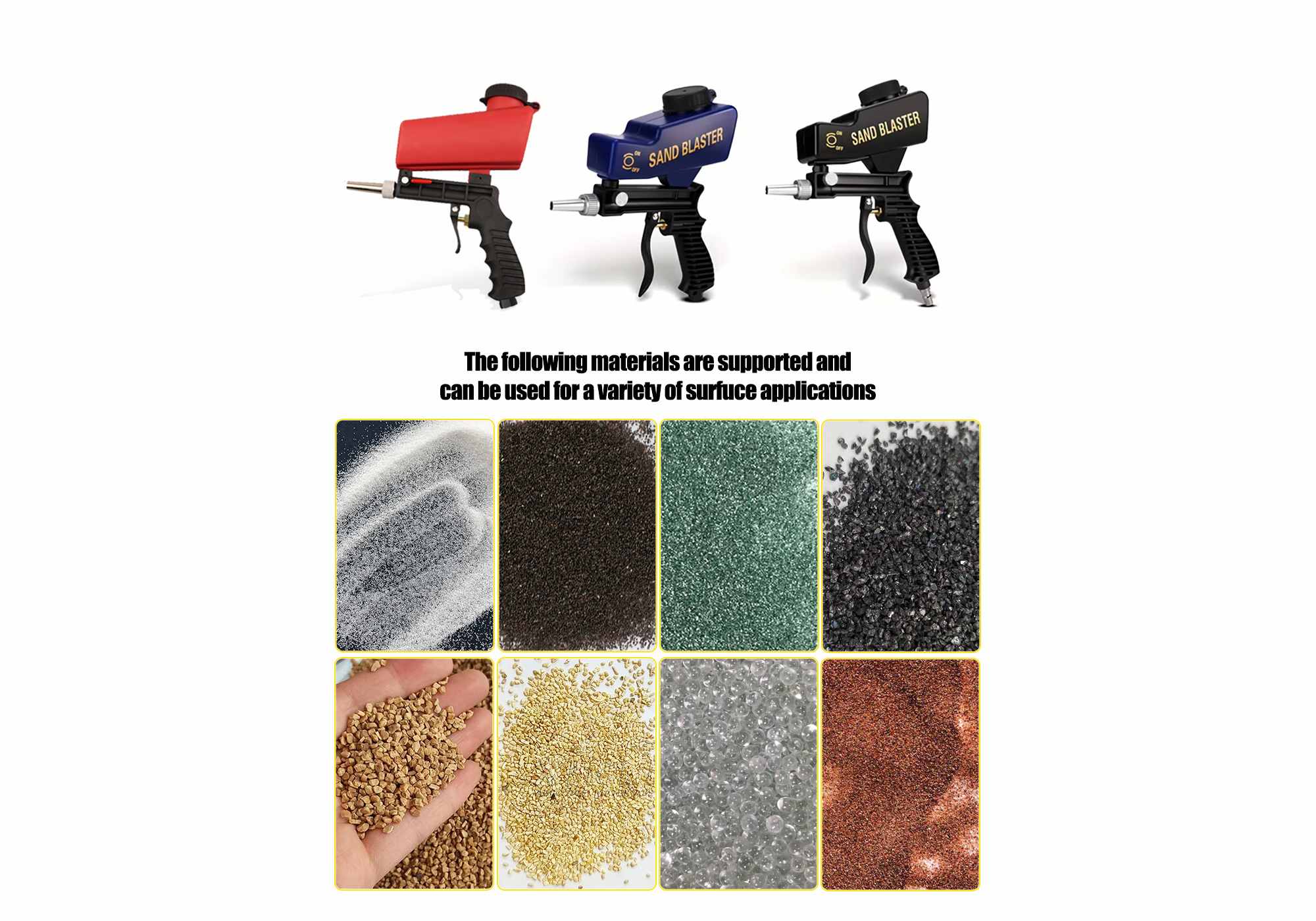

1. Overview of Sandblasting Gun Products

The sandblasting gun is an indispensable core device in the sandblasting system. Its working principle is to accelerate sandblasting abrasives to high speeds using compressed air, and then use the high-speed flow of abrasives to clean, de-rust, polish, and engrave the surface of objects. New sandblasting gun products have the following advantages, helping users improve operational efficiency and surface treatment quality:

High-Efficiency Sandblasting Gun

The new generation of sandblasting guns is designed to improve sandblasting efficiency and has the following advantages:

High durability: The sandblasting gun uses high-strength alloy materials with excellent wear resistance, maintaining stable performance during long periods of high-load operation.

Ergonomic design: The gun body is ergonomically designed, ensuring that operators do not experience fatigue during prolonged use, improving work comfort.

High-efficiency spraying: The flow rate and spraying pressure of the sandblasting gun are adjustable, allowing for precise control according to the processing needs of different materials, ensuring the uniformity and efficiency of the sandblasting effect.

Adaptable to various abrasives: This sandblasting gun is suitable for a variety of sandblasting abrasives, such as white corundum, brown corundum, silicon carbide, etc., meeting the needs of different customers.

2. Selection and Application of Sandblasting Abrasives

The selection of sandblasting abrasives has a crucial impact on the sandblasting effect. The right abrasive material is crucial for ensuring the efficiency and quality of the sandblasting process, while unsuitable abrasives can lead to surface damage and inefficiency. Several common high-performance sandblasting abrasives available on the market are as follows:

White Fused Alumina Abrasive

White fused alumina is a high-hardness abrasive made from high-purity bauxite through high-temperature smelting in an electric arc furnace. It is widely used in fine grinding and polishing, suitable for surface treatment of materials such as glass, metal, and ceramics.

High hardness: White fused alumina has a Mohs hardness close to 9, making it suitable for processing hard materials and effectively removing oxide layers and oil stains.

Smooth surface: Due to its excellent surface smoothness, white fused alumina is particularly suitable for applications requiring a fine surface finish.

Wide application: White fused alumina can be used not only for sandblasting but also for waterjet cutting and precision polishing. Its demand is growing rapidly, especially in the optical devices, semiconductor, and automotive parts industries.

Brown Fused Alumina Abrasive

Brown fused alumina is a medium-hardness abrasive produced by smelting bauxite with coke and other raw materials at high temperatures. Compared to white fused alumina, brown fused alumina has higher toughness and is widely used in rough grinding and removing thick layers of dirt.

High toughness: Brown fused alumina has strong toughness, making it suitable for high-impact applications such as rough grinding and rust removal.

Strong adaptability: It can be used with various sandblasting machines and guns and is widely used in surface treatment of metals such as steel, cast iron, and aluminum alloys.

Cost advantage: Compared to white fused alumina, brown fused alumina offers better cost-effectiveness, making it suitable for large-scale industrial production.

Green Silicon Carbide Abrasive

Green silicon carbide is a very hard abrasive with good electrical conductivity, widely used in ultra-precision polishing, laser cutting, and high-precision parts processing. Its hardness and wear resistance make it an indispensable material in precision machining.

Ultra-high hardness: Green silicon carbide has a hardness close to diamond, making it suitable for materials requiring high precision and high hardness.

Precision grinding: Suitable for precision machining of glass, ceramics, and optical components, providing extremely high processing accuracy and surface quality.

Wide application: Green silicon carbide is widely used in high-end manufacturing industries such as optics, semiconductors, and aerospace, making it an ideal choice for high-precision machining. 3. Synergistic Effects of Sandblasting Guns and Abrasives

The combination of sandblasting guns and abrasives is a key factor influencing the quality and efficiency of surface treatment. The combination of high-efficiency sandblasting guns and high-quality abrasives provides a more efficient and economical surface treatment solution.

For example, sandblasting guns paired with white corundum abrasives can provide extremely high surface finish, widely used in the processing of optical devices and precision mechanical components; while brown corundum abrasives are more suitable for large-scale metal surface rust removal and polishing. For high-precision industries, the combination of green silicon carbide abrasives and high-efficiency sandblasting guns can achieve ultra-precision polishing and efficient grinding, meeting the stringent requirements for precision and surface quality in modern high-end manufacturing.

4. Industry Prospects and Future Development

With the continuous development of industrial automation, intelligence, and high-precision manufacturing, sandblasting technology is also continuously upgrading. From basic surface cleaning to fine polishing and engraving, the application fields of sandblasting guns and abrasives are constantly expanding. In the future, sandblasting equipment will gradually develop towards intelligence and automation. Intelligent sandblasting guns will achieve more precise and efficient surface treatment by introducing sensors and artificial intelligence technology.

Environmental Protection and Green Manufacturing

With the increasing environmental protection requirements, green manufacturing has become the main development direction of future manufacturing. The research and application of environmentally friendly abrasives will become a future development trend in the sandblasting industry. Reducing energy consumption and pollutant emissions in the production process will drive sandblasting technology towards sustainable development.

Conclusion

The innovative combination of sandblasting guns and abrasives has become an indispensable part of modern surface treatment technology. Through continuous innovation, sandblasting guns and abrasive products will continue to drive the upgrading of surface treatment technology in various industries, meeting the growing demand for high precision and high efficiency. Whether in metal, glass, ceramics, or high-precision industries such as optics and semiconductors, sandblasting technology will continue to play an important role in future development.