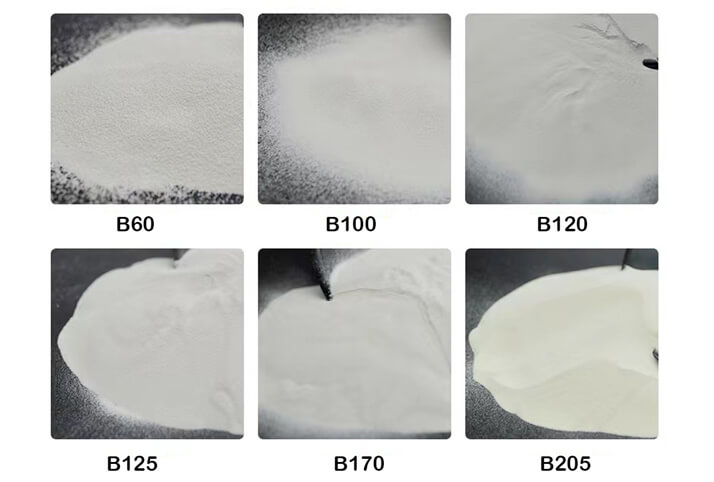

The ceramic sand that has received more attention in recent years is zirconium oxide beads (composition: ZrO₂56%-70%, SIO₂23%-25%), which are spherical, smooth surface without damaging the workpiece, high hardness, good elasticity and multi-angle rebound of sand grains during sand blasting, which is ideal for complex workpieces (metal, plastic).

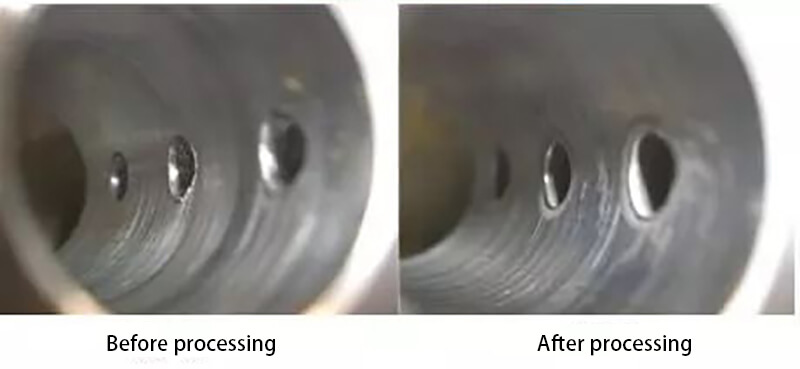

1.Cast and forged pieces of rough surface, heat treatment after the workpiece cleaning and polishing

① sandblasting can clean up all the dirt on the surface of the workpiece after casting and forging, welding and heat treatment (such as oxidation, oil and other residues), and polish the surface of the workpiece to improve the finish of the workpiece and play a role in beautifying the workpiece.

②Sandblasting cleaning can make the workpiece to reveal the uniform and consistent metal colour, so that the appearance of the workpiece more beautiful, to beautify the role of decoration.

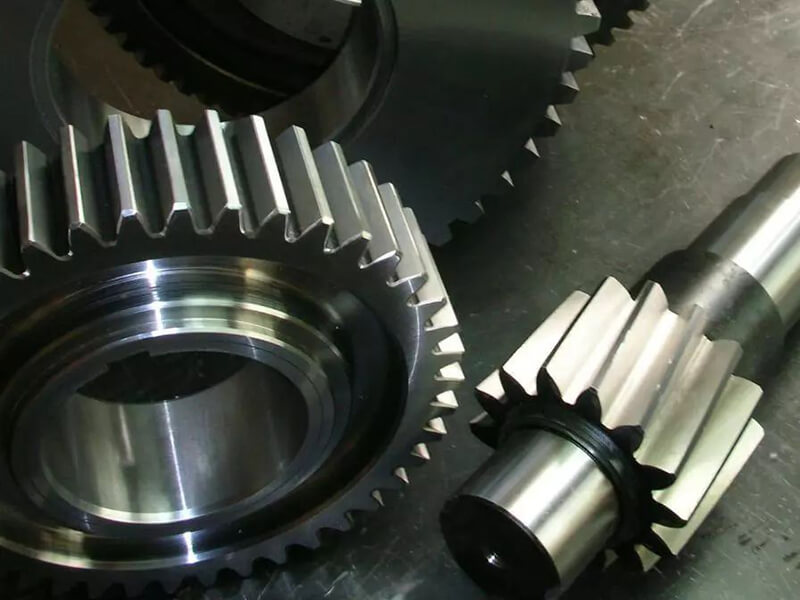

2.Machined parts burr cleaning and surface beautification

Sandblasting can clean the workpiece surface of the tiny burr, and make the surface of the workpiece more flat, eliminating the harm of burr, improve the grade of the workpiece. And sandblasting can hit the junction of the surface of the workpiece very small rounded corners, so that the workpiece appears more beautiful, more precise

3.Improve the mechanical properties of the parts

Mechanical parts by sandblasting, can produce a uniform fine bumpy surface on the surface of the parts (foundation pattern), so that the lubricant is stored, so that the lubrication conditions improve, and reduce noise to improve the use of machinery time.

4.Light finishing role

①Polish the surface of various workpieces to make the surface of the workpiece more beautiful.

②To make the workpiece smooth and non-reflective requirements.

③For some special purpose workpiece, sandblasting can achieve different reflective or matt at will. Such as stainless steel workpiece, wooden furniture surface matte, frosted glass surface pattern, as well as the surface of the fabric hair processing.

5.Stress relief and surface strengthening

By sandblasting the surface of the workpiece to eliminate stress and increase the surface strength of the workpiece, such as springs, gears, machining tools and aircraft blades and other workpiece surface treatment.

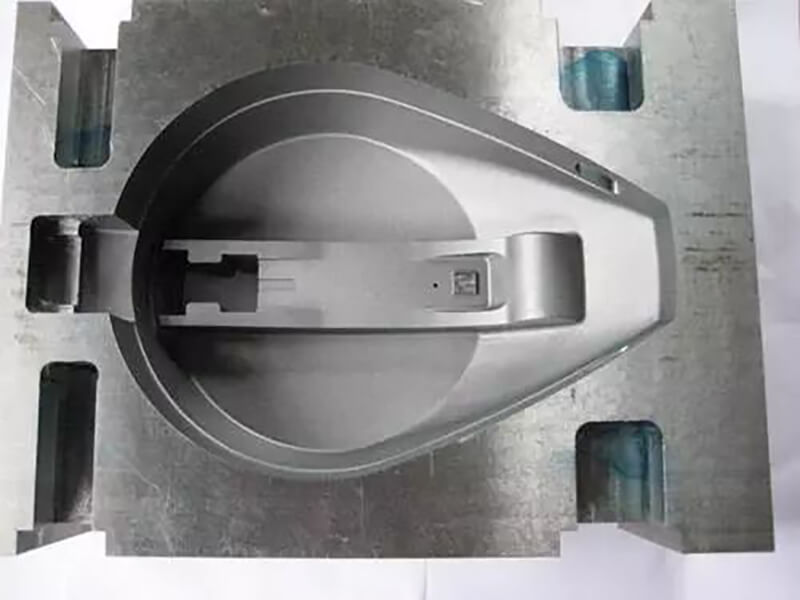

6.Mould cleaning

Die surface argon matte surface treatment, graphic production, as well as die cleaning, not to hurt the surface of the mold, to ensure the accuracy of the mold, including aluminum alloy die-casting die, aluminum extrusion mold, tyre mold, glass bottle mold, etc.