Anyone who has worked in a sandblasting workshop knows that choosing the right abrasive is like a traditional Chinese medicine doctor prescribing herbs – it requires careful consideration and matching the abrasive to the specific task. White fused alumina, with its high hardness and toughness, is a “star player” in the sandblasting world. However, you might not know that even within white fused alumina abrasives, different grit sizes produce vastly different results. Today, let’s talk about this seemingly simple but actually quite complex topic of grit size classification.

I. “Coarse, Medium, and Fine”: The Basic Three-Tiered System

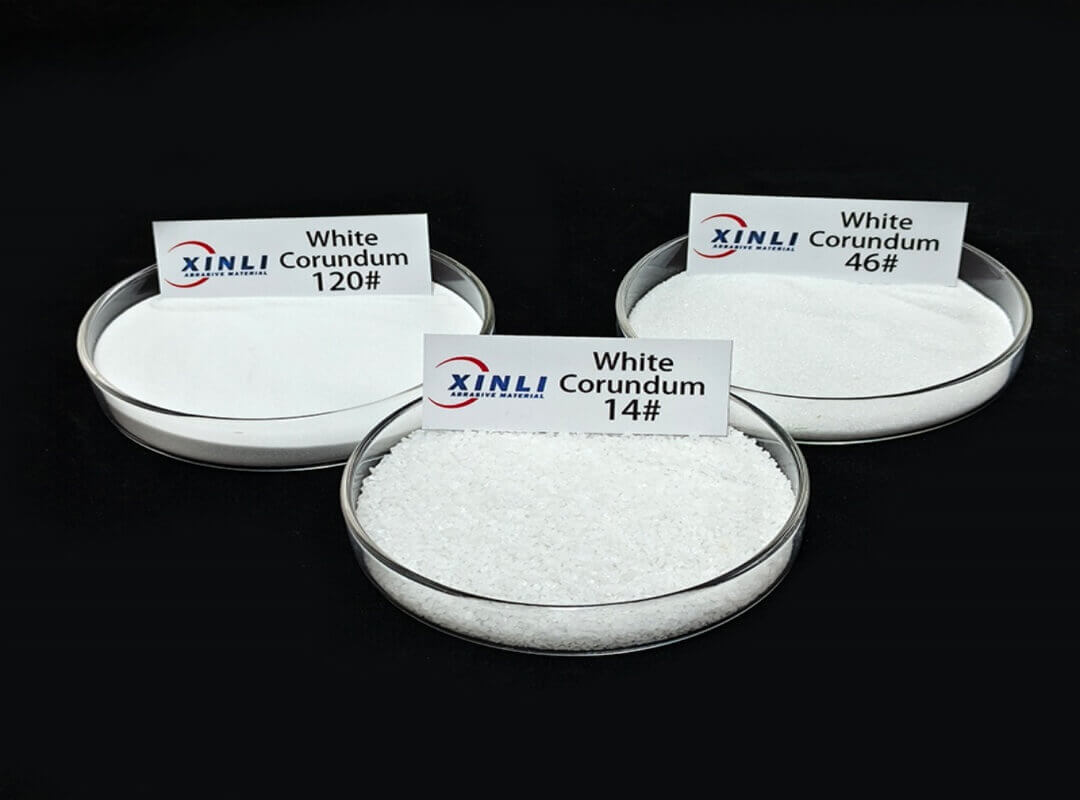

Experienced sandblasting professionals typically divide white fused alumina abrasives into three main categories: coarse, medium, and fine. This classification sounds simple, but it embodies decades of accumulated experience. Coarse grit generally refers to the range of 20 mesh to 60 mesh. What does that mean? It means the particle diameter is approximately between 0.85 millimeters and 0.25 millimeters. If you hold a handful, you can clearly feel the granular texture. This type of abrasive has strong impact force and is suitable for “heavy-duty” work. For example, cleaning large castings: the surface of a casting after pouring is covered with a layer of molding sand and oxide scale, which is very hard and requires the strong impact of coarse grit. Old Zhang in our factory often says, “To deal with those ‘stubborn’ surfaces, you have to use coarse grit, just like using a steel wool pad to scrub a pot.”

Medium grit is between 80 mesh and 180 mesh (0.18 millimeters to 0.08 millimeters), and it’s the most commonly used “all-rounder.” Calling it “medium” not only refers to its medium grit size but also to its moderate applicability. It’s neither as “violent” as coarse grit nor as “gentle” as fine grit. For surface pretreatment of steel structures, weld cleaning, and rust removal of some ordinary parts, medium grit is the right choice. It provides a balanced surface treatment effect, ensuring cleanliness without producing excessive surface roughness. Fine grit starts from 220 mesh and goes even finer. This type of abrasive is very fine, feeling like flour to the touch. Don’t underestimate it because of its fineness; delicate work relies on it. For surface cleaning of precision castings, mold polishing, and the treatment of some high-end decorative surfaces, fine sand is absolutely essential. Mr. Li, the foreman in our workshop responsible for precision parts, has a favorite saying: “Coarse sand cures the disease, fine sand beautifies.” This perfectly illustrates the principle.

II. Grading Standards: More Than Just “Sifting”

When it comes to specific grading, laymen might think it’s simply a matter of using sieves with different mesh sizes. That’s true, but not entirely. National standards (GB/T) and industry standards have clear regulations, such as the grading system from F4 (coarsest) to F1200 (finest). Each grade corresponds to a strict particle size distribution range. However, in practice, experienced technicians also emphasize “uniformity.” What does this mean? It means that the particles in the same bag of sand should be roughly the same size. If there are both coarse and fine particles, the surface effect after blasting will be uneven. Good sand should have a steep particle size distribution curve, not a flat one.

III. Applicable Scenarios: Different Particle Sizes for Different Jobs

Coarse sand (20-60 mesh) is mainly used in heavy industry. Besides the casting cleaning mentioned earlier, it’s indispensable for surface treatment of large steel structures before painting. For example, bridges, ships, and storage tanks – these large structures are exposed to the elements year-round, and their surface oxide layers are thick and hard. Coarse sand can quickly remove old coatings and rust, exposing the metal substrate. However, it’s important to note that coarse sand has a strong impact force, so it shouldn’t be used on thin sheet metal, otherwise it can easily deform. We learned this the hard way: once, we used 40-mesh sand to treat a 3mm thick steel plate, and the plate ended up looking like a wave, forcing us to scrap it and start over.

Medium sand (80-180 mesh) has the widest range of applications. In the automotive industry, it’s used for pre-treatment of car body panels before painting; in the pressure vessel industry, for cleaning welds before flaw detection; and in general machinery manufacturing, for surface roughening of parts. Its characteristic is its versatility – it provides good cleaning results and creates a moderate anchor pattern (the fine bumps and depressions on the surface), which is beneficial for coating adhesion. The production manager at our factory uses a vivid analogy: “Medium-grit sand is like home-style cooking—not the most refined, but the most satisfying and most commonly used.”

Fine-grit sand (220 mesh and above) is reserved for precision manufacturing. Precision parts in the aerospace industry, medical device components, and the sandblasting of high-end electronic product casings all require fine-grit sand. It can control the surface roughness (Ra value) to a very low level while achieving a uniform matte finish. Last year, we sandblasted a batch of surgical instruments for a medical device company using 320-mesh sand. The requirements were so high that the finished products had to be inspected under specific lighting conditions, with no visible scratches or unevenness allowed. Liu, the person in charge of this job, was so stressed that he was losing his hair. “This isn’t sandblasting, this is embroidery,” he said with a wry smile.

IV. The Art of Sand Selection: A Combination of Experience and Science

How do you choose the right grit size in practice? This involves both scientific calculation and experienced judgment. First, you need to consider the material of the workpiece. Harder materials can use coarser sand, while softer materials (such as aluminum and copper) require fine sand. Second, consider the thickness of the workpiece; thin pieces should not use coarse sand. Third, consider the final surface requirements. For coatings, consider the coating thickness; for decorative purposes, consider the aesthetics. Our factory’s technical department has summarized a simple mnemonic: “Hard and thick, use coarse; soft and thin, use fine; for decoration, go finer; for adhesion, choose medium-fine.” But this mnemonic is just a starting point; specific projects require specific analysis. For example, for stainless steel, if it’s for the inner wall treatment of chemical equipment, medium-coarse sand might be used for quick cleaning; but for food machinery, fine sand is necessary to ensure easy cleaning and disinfection.

Many factories are now promoting “one sand, one specification,” which means establishing an optimal sandblasting parameter profile for each product, with grit size selection being a key element. Establishing this profile is time-consuming, requiring repeated testing, but once established, it becomes a valuable asset. The profile we developed for a certain car engine cylinder block shows that using 100-mesh white corundum sand, at a pressure of 0.5 MPa and a distance of 200 mm, the surface roughness perfectly meets the optimal coating requirements. This data was obtained after more than thirty trials. V. Common Misconceptions and Precautions

Beginners often make several mistakes. First is the misconception that “the coarser the better,” believing that coarser grit cleans faster. However, excessively coarse grit can cause deep surface damage, requiring subsequent repairs and ultimately wasting time. Second is mixing different batches of grit, which is a major no-no. Even if the grit has the same grade number, the actual particle size distribution may differ between batches, leading to uneven surface treatment results. Third is neglecting the number of times the grit has been recycled. White corundum grit can be recycled multiple times, but with increased use, the particles gradually become rounder and finer, reducing cleaning efficiency. Experienced technicians can judge whether the grit needs replacing by the sound and color of the grit stream.

Our workshop supervisor, Old Chang, often says, “Grit is like soldiers; you need to understand the characteristics of each soldier to win the battle.” This statement is simple, but profound. Particle size classification may seem like a simple physical parameter, but it connects to knowledge from multiple fields, including materials science, surface engineering, and fluid mechanics. The spectrum of white corundum grit, from coarse to fine, is like a complete toolkit. A true master craftsman doesn’t just use one or two tools, but can accurately select the most suitable “tool” based on different “conditions.” In this era where surface quality is increasingly important, a deep understanding and skillful application of particle size classification has become an indispensable skill. It’s not flashy, but it genuinely affects product quality and lifespan. Perhaps this is one of those “invisible keys” in industrial manufacturing.